Emerging Trends Shaping Plastic Extruders in 2026

You see Plastic Extruders improving rapidly in 2026. Learning about new technology helps you stay on top.

- The extruded plastics market will be worth $184.41 billion in 2026. It will grow at 3.91% each year until 2034.

- Companies use recycled materials and more efficient systems to generate less waste and help the planet.

Key Takeaways

- The plastic extruders market will reach $184.41 billion by 2026. This is because more people want sustainable materials.

- Smart manufacturing uses automation and real-time monitoring. These help make products faster and better.

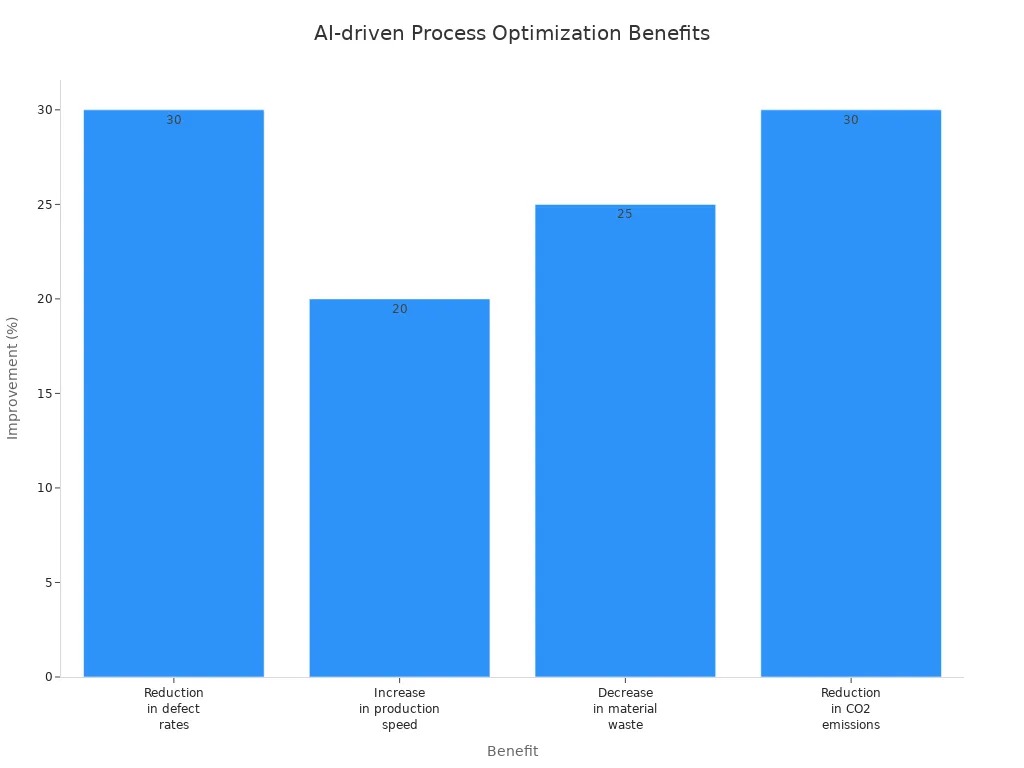

- AI and predictive technology help lower defects by 30%. They also cut waste by 25%. This makes the process work better.

Smart Manufacturing for Plastic Extruders

Smart manufacturing is changing how Plastic Extruders work. New technology makes production faster and easier to control. Industry 4.0 brings automation and digital tools to factories. You can track each step and make quick changes to improve quality.

Automation & Digitalization

Automation helps extrusion lines run smoothly. Robots and smart drives lower mistakes and boost output. Some common automation tools are articulated arm robots, AGVs, and machine vision systems. These tools move materials, check products, and do simple tasks.

Automation Technology | Description |

|---|---|

Articulated Arm Robots | These robots are flexible and often used in plastic extrusion. |

Automated Guided Vehicles (AGVs) | AGVs move materials quickly during manufacturing. |

Machine Vision | Machine vision checks quality and watches the extrusion process. |

Digitalization makes work faster and improves product quality:

- Smart production uses sensors and AI to watch and adjust things in real time.

- Predictive maintenance looks at wear and use data to stop surprise breakdowns.

- AI helps find defects and makes processes better, so products are of higher quality.

For example, you can use IoT sensors to watch machines. This helps cut down on machine stops and keeps quality steady. Smart sensors also spot wear early, so you can fix things before they break.

Digitalized tooling systems make work more exact by automating jobs. These tools change settings right away if something is off, so products stay high quality and waste goes down.

Sensors and Real-Time Monitoring

Sensors help extrusion lines work well. Systems like UltraGauge+ and WARP watch wall thickness and size as you work. These sensors give instant feedback, so you can fix things fast and avoid problems.

- UltraGauge+ checks wall thickness and size, helping keep quality high and waste low.

- WARP uses many sensors to give real-time data, so you can change things right away.

- LaserLinc's UltraGauge+ system checks sizes all the time and gives instant feedback, so you can fix problems quickly.

Seeing changes right away means you can fix issues before they slow you down. Closed-loop control systems change things automatically, so you spend less time fixing and more time making good products. You use less material and make more products, so your work is more efficient.

AI & Predictive Tech

AI Process Optimization

AI can help make your extrusion process smarter and faster. These systems find problems early and help you fix them. Many companies see big changes when they use AI. For example, one car company had 30% fewer defects. They also wasted 25% less material. Advanced sensors help you make products 20% faster and keep quality high.

Benefit | Measurement |

|---|---|

Reduction in defect rates | 30% |

Increase in production speed | 20% |

Decrease in material waste | 25% |

Reduction in CO2 emissions | 30% |

Decrease in cycle times | Up to 50% |

Sustainability Innovations

Bioplastics & Recycled Materials

More companies use bioplastics and recycled materials now. These materials help meet tough environmental rules. Customers want greener products. Many bioplastics work well in Plastic Extruders. They are strong and better for the planet.

Bioplastic Type | Source | Key Property | Common Extrusion Use |

|---|---|---|---|

PLA | Corn, sugarcane | Biodegradable | Food packaging films |

TPS | Starch | Compostable | Agricultural films |

PHAs | Microbial process | Biocompatible | Medical tubing |

Energy-Efficient Systems

You save money and lower emissions with energy-efficient systems. Smart controls watch machines and change settings to save power. High-performance materials help control heat, so you use less energy.

- Smart sensor networks and live data analytics watch your process.

- Special polymers melt at lower temperatures, so you need less heat.

- Connecting motors, heaters, and cooling systems saves even more.

- Advanced drives, induction heating, and smart cooling save 25–40% energy.

- Waste heat recovery and digital monitoring help you save extra.

Tip: Energy-efficient upgrades lower bills and help the planet.

Circular Production & Waste Reduction

You cut waste and work better with circular production models. You control raw materials, improve cycles, and use real-time data to fix problems fast.

- Calculate and control raw materials to stop waste.

- Make cycles better to use materials and reduce downtime.

- Train your team to follow good steps and learn about waste.

- Give rewards to get everyone working on waste reduction.

- The circular economy helps you use resources well.

- You reuse, repair, recycle, and remanufacture.

- This system lowers plastic waste and protects nature.

Note: As rules get tougher, you must show you care for the planet. Circular production and waste reduction help you stay ahead and build a good reputation.

Material Advances in Extrusion

High-Flow & Dual-Nozzle Systems

High-flow systems help you make products faster. These systems push polymers through quickly. You can handle tough materials and make more items in less time. Dual-nozzle setups let you use two materials at once. You can make layered or mixed products with better features.

Tip: Dual-nozzle systems help you make special products for different needs.

Recyclable Monomaterials

Recyclable monomaterials help you comply with new rules and protect the environment. These materials use just one kind of polymer. This makes recycling easy. You make less waste and help the planet. Many companies now use monomaterials to support circular production.

- Monomaterials make recycling easy.

- You cut down on waste and help the environment.

- Customers like products that are easy to recycle.

Data Integration & Industry 4.0

IIoT in Extrusion Lines

You can use IIoT to make extrusion lines smarter. It lets you manage your plant and see data from far away. You can control your process from anywhere. Sensors work together and send data right away. You see what is happening as it happens. You can:

- Watch important numbers to check your process.

- Use smart tools to guess problems before they stop your line.

- Make old lines better with TSM controls for more efficiency.

- Change machine data into tips that help quality and uptime.

- Fix your process quickly with real-time checks.

- Always measure speed and temperature for steady production.

- Look at data to find patterns and fix problems fast.

Tip: Real-time data helps you change things fast and keep your process steady.

Data-Driven Decisions

You can use data to make better choices in your plant. Many companies use data now to work better. Here are some ways to use data-driven choices:

Example | Description |

|---|---|

ABC Plastics | Used machine learning to guess problems before they happen, making work smoother. |

Predictive Maintenance Alerts | Checked old data to know when machines need care, so you avoid breakdowns. |

Energy Consumption Monitoring | Found times when energy use was too high, so you save power and money. |

Integrated Quality Control | Changed settings automatically with real-time checks, so you need less manual work. |

Note: Using data helps you cut waste, save money, and keep quality high.

Simulation Tools

Simulation tools help you plan and fix problems before they happen. You can make models to see how materials act in Plastic Extruders. This helps you spot defects or other issues early. You can test different settings to find the best way to run your line.

Contribution of Simulation Tools | Description |

|---|---|

Modeling Material Behavior | Make virtual models to guess how materials act during extrusion. |

Predicting Defects | Find problems like warping or uneven thickness before they reach production. |

Enhancing Design Efficiency | Improve temperature, speed, and pressure for better quality and efficiency. |

Simulation tools help you make smart choices and keep your process running well.

Market Trends for Plastic Extruders

Market Growth & Drivers

The global market for Plastic Extruders is getting bigger. Asia Pacific is the top region. Its market size is USD 70.38 billion in 2024. By 2034, it will reach USD 104.18 billion. The growth rate is 4.00% each year. North America is also growing fast. People want lightweight and strong materials for cars, buildings, and everyday items.

Region | Projected Market Size (2024) | Projected Market Size (2034) | CAGR (2026-2034) |

|---|---|---|---|

Asia Pacific | USD 70.38 billion | USD 104.18 billion | 4.00% |

Many things help this market grow:

- More people want plastic products that are light and cheap for cars and packaging.

- Building projects need more plastic pipes and window frames.

- Companies use more biodegradable and recyclable plastics, so they change how they work.

Regulatory Impacts

You need to follow new rules. These rules are about being green and handling waste better. Groups like the EPA and European Commission make rules to cut down on plastic waste. Some countries ban single-use plastics. Others say products must have recycled plastic. The European Union wants all plastic packaging to be reusable or recyclable by 2026.

Note: You may need to buy new machines and change how you work to follow these rules.

Sector-Specific Opportunities

There are new chances in some areas:

Sector | Opportunities |

|---|---|

Packaging | More people want packaging that is light and good for the planet. |

Automotive | Electric cars need special plastic parts. |

Construction | New plastic ideas help save money and work better. |

More factories and new technology make these areas grow. You can do well if you focus on new ideas and caring for the environment.

You notice smart manufacturing, AI, and sustainability are making plastic extruders different. If you want to keep up, you can:

- Put IoT sensors on machines to watch them live.

- Use automated lines to make products better.

- Spend money on research to find new materials.

Future Trend | Impact |

|---|---|

Self-Reconfiguration | Fewer mistakes, fewer stops |

Recycled Materials | Saves money, helps the planet |

You help change the future when you try new technology and invest in it.

FAQ

What is the main benefit of using AI in plastic extrusion?

AI helps you find problems early. You can make better products. You use less material and stop wasting time. Your machines keep working without many stops.

How do bioplastics help your extrusion process?

- You follow the new green rules.

- You make products that are better for the earth.

- You get more customers who care about the planet.

Can you upgrade old extruders for Industry 4.0?

Upgrade Option | Benefit |

|---|---|

IoT Sensors | You can watch machines live. |

Smart Controllers | You control the process better. |

Data Analytics | You work faster and smarter. |