The Five Major Advantages of Audop PVC Fully Automatic Material Blending System

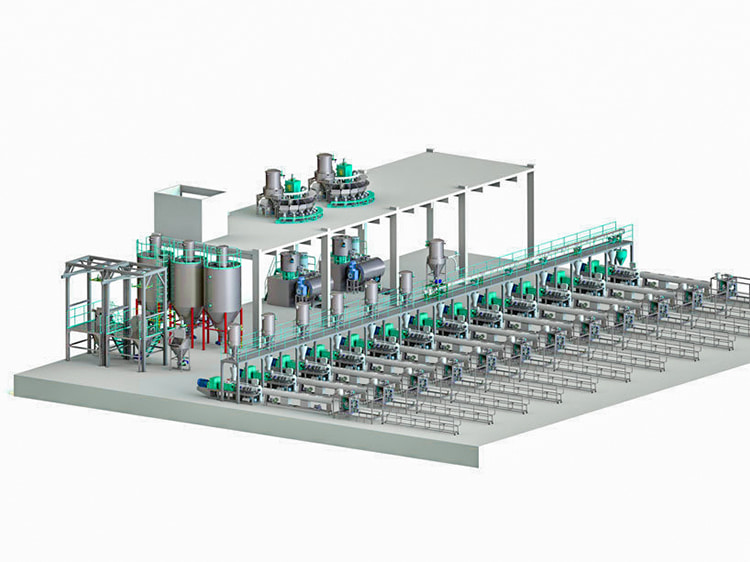

Audop PVC Fully Automatic Material Blending System delivers precise weighing, dust-free conveying, and uniform high-speed mixing for PVC production. Designed for stable quality, higher efficiency, and fully automated operation, it ensures reliable compound preparation for PVC profiles, pipes, sheets, and more.

When it comes to PVC (polyvinyl chloride) production, consistency, efficiency, and environmental control aren't just nice-to-haves - they're everything. That's where the Audop PVC Fully Automatic Material Blending System comes in, offering an automated, intelligent, and highly reliable solution to the age-old problem of mixing PVC resin, additives, stabilizers, and fillers. In this article, we'll explore what exactly this system is, how it's put together, and the five big advantages that make it a game-changer.

What Is a PVC Fully Automatic Material Blending System?

At its core, a PVC fully automatic material blending system is a sophisticated production line component designed to take raw powder or granular materials - like PVC resin, calcium carbonate, plasticizers, stabilizers, colorants, and other additives - and precisely measure, transport, mix, and deliver them in a fully automated way. Rather than relying on manual weighing and mixing (which introduces human error, inconsistencies, and dust), this system streamlines everything under centralized computer control.

The Audop PVC Fully Automatic Material Blending System integrates a number of subsystems - from feeding and conveying to weighing, mixing, storage, and even dust control. The aim is simple yet powerful: produce a perfectly homogeneous PVC 'compound' ready for downstream processes like extrusion, pelletizing, or profile production.

Key Components of the System

To understand its advantages, it helps to know the main building blocks of the system. A typical automatic blending setup includes:

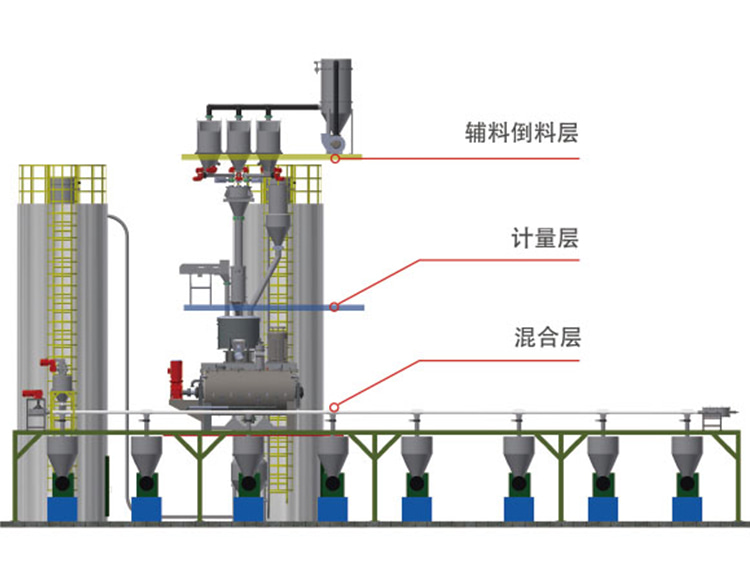

- Material Collection & Feeding Subsystem

- Receives raw materials from bags, big-bags (totes), or silo trucks.

- Uses pressure-balanced pneumatic or mechanical conveying (e.g., pipe-chain, negative-/positive-pressure) to move powders to storage bins or directly to metering units.

- Weighing & Dosing Unit

- Separate weighing hoppers for the main resin and for minor additives.

- High-precision metering screws (sometimes with anti-sticking coatings) ensure that each recipe is accurately followed.

- Dynamic, real-time adjustment to maintain accuracy even when materials flow or properties shift.

- Mixing Module

- Usually consists of a hot mixer (or high-speed mixer) and a cold mixer: the first raises the temperature and begins dispersion; the second cools and finalizes homogenization.

- The mixers are tightly sealed to reduce dust, and include temperature control systems.

- Storage & Re-Circulation System

- After mixing, the compound may be temporarily stored in homogenizing bins ('smoothing silos”) to ensure uniformity.

- From there, material is conveyed (via vacuum or pneumatic systems) to the extrusion or downstream equipment.

- Dust Collection & Centralized Control

- Closed-loop dust removal systems ensure minimal environmental impact and a clean workspace.

- A central control system (PLC + PC) manages recipe data, monitors process parameters, logs faults, and offers remote monitoring and multiple recipe storage.

The Five Major Advantages

Now, let's dive into the five major benefits that make this system such a smart investment.

- Consistent Product Quality:

Because the system precisely weighs and doses every component - resin, fillers, stabilizers - recipe accuracy is dramatically improved. This leads to a highly uniform compound. In turn, downstream products (like PVC profiles, pipes, or sheets) have fewer defects and more consistent mechanical and aesthetic properties. - Higher Efficiency & Throughput

Automating the feeding, weighing, and mixing steps eliminates many labor-intensive tasks, reducing cycle times and increasing output. Plus, the system can run continuously (24/7), delivering raw material to the extruder without interruptions. - Reduced Waste, Improved Safety

The fully enclosed nature of the system minimizes material spillage and dust, reducing environmental contamination and improving worker safety. Dust collection subsystems help keep the workspace clean, while sealed transport lines prevent powder loss. - Precise Control & Traceability

With modern PLCs and industrial PCs, the system stores multiple recipes, logs each batch, and can generate real-time reports. This traceability is invaluable for quality control and regulatory compliance. Operators can quickly switch formulas without manual reworking, which is both time-saving and error-reducing. - Scalability & Flexibility

Whether a plant is making rigid pipe, flexible profiles, or WPC (wood-plastic composites), the system can be configured accordingly. The modular design (storage bins, mixers, dosing units) allows for expansion or recipe changes. If you want to add a new color, a special additive, or a whole new product line - the system can adapt.

Why It's a Smart Choice for PVC Manufacturing

Imagine a production facility where the raw ingredients zip into the system via closed pipelines, get weighed with laser-like precision, swirl through mixers, and then glide directly into an extruder - all without human hands touching a bag or manually measuring anything. That's not just automation: that's elegant efficiency.

Using the Audop PVC Fully Automatic Material Blending System means more than just improving quality - it means reducing labor costs, minimizing waste, lowering health risks, and building a production process that's ready for future growth. In a competitive market, these advantages don't just help - they can distinguish your operation.

In short, the Audop PVC Fully Automatic Material Blending System is more than a piece of equipment: it's a strategic ally in modern PVC manufacturing. By combining precision, automation, safety, and flexibility, it enables businesses to produce better PVC compounds more reliably and more sustainably than ever before.