What is The Function of The Vacuum Feeder

The Vacuum Feeder is an advanced pneumatic conveying solution designed for clean, efficient, and automatic transfer of powder and granular materials. Using negative pressure (vacuum) technology, it gently transports materials through enclosed pipelines-keeping your production environment dust-free and contamination-free. Whether used in plastic processing, food production, chemical handling, or pharmaceutical manufacturing, this system ensures a continuous and reliable feeding process with minimal manual labor. With its compact structure, easy cleaning, and smart automation control, the Vacuum Feeder is the ideal choice for modern factories looking to improve efficiency and hygiene in material conveying operations.

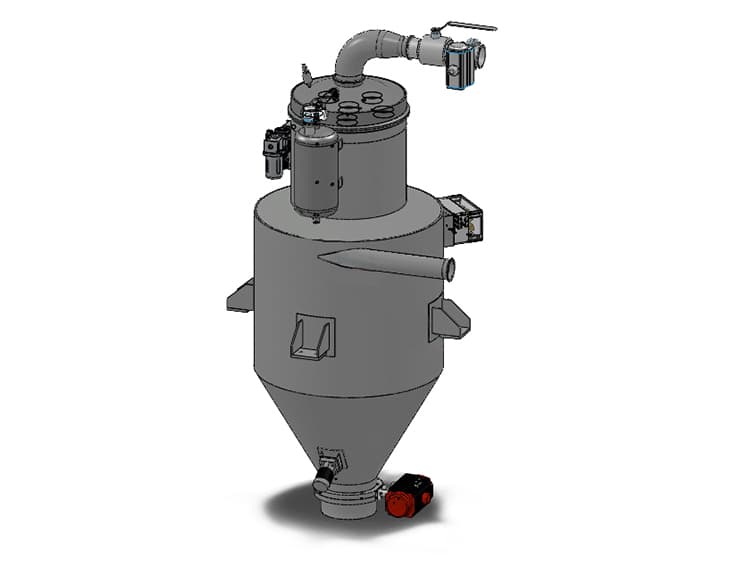

Imagine a production line humming like a well-oiled machine: powders and granules being whisked from one station to the next without clouds of dust, without one worker traipsing back and forth with a bucket, without mess. That's where the humble yet clever device called a vacuum feeder steps in. In more formal terms, the device you'll often see listed as the Vacuum Feeder (see more here: Vacuum Feeder) plays a key role in industrial material handling. But let's drop the jargon and see what it actually does, what it's made of, why it's a favorite, and where you'll find it in action.

What does it do?

At its core, a vacuum feeder is all about transporting powders and small granules from one place to another-safely, cleanly, and efficiently. Rather than relying on someone pouring or scooping material, or maybe using a simple conveyor belt that's exposed and messy, the vacuum feeder uses a vacuum (negative pressure) to suck material through a pipeline, deposit it into a hopper, machine, or packaging line, and thereby automate a portion of the feeding process. According to one manufacturer, the vacuum feeder 'is a vacuum conveying equipment for powdery materials, granular materials, and powder-granule mixtures. It can automatically convey various materials into the hoppers of equipment such as silos, packaging machines, injection molding machines, and crushers.”

In short: it takes material A, moves it cleanly, and deposits it into machine B, without dust flying everywhere, without the material getting contaminated, and without unnecessary manual labor.

Key components - the 'what's inside”

Here's how the machine is built, so you can imagine how the magic happens:

- A vacuum pump (often oil-free and water-free) which creates the negative pressure that pulls the material.

- A suction nozzle or hose through which ambient air and the material are drawn in.

- A conveying hose or pipeline that carries the mixture of air + material to a hopper or separation chamber.

- A filter (could be a PE filter or stainless steel 316L) and a method of back-blowing (compressed-air cleaning) to keep the filter from clogging.

- A vacuum hopper (where the material/air separation happens) and possibly automatic material-level sensors or controls so the system knows when the downstream hopper is full or needs more.

- Pneumatic discharge door or directional valve: at the right moment the material is dumped into the next station. The timing and control can be automatic.

Putting this together: you turn on the vacuum pump → negative pressure draws air + material in through the suction hose → material is carried via pipeline to hopper → material/air separated → material goes to machine, air is vented/filtered → filter gets pulse-cleaned so system keeps working.

What are the benefits?

Why choose a vacuum feeder rather than a simpler feeding technique? Here are several good reasons:

- Dust-free and enclosed conveying: Because the material is transported through enclosed piping, you avoid dust leakage, cross-contamination of materials, and you improve the cleanliness of the workplace.

- Space-saving and flexible layout: The conveyor pipes can navigate narrow spaces, go long distances perhaps, and don't take up as much floor space as big hoppers or open conveyors.

- Reduced manual labour: The system can feed automatically, stop when the level is reached, start when more is needed, so less human intervention is required.

- Material quality preservation: The enclosed system means less chance of materials getting damp, contaminated or mixed with foreign substances-important if you're dealing with fine powders or food/chemical materials.

- Flexible, efficient, cost-effective: With fewer moving parts, simpler installation, and often capable of serving multiple machines in one plant, the vacuum feeder can pay off in efficiency and maintenance savings.

All of this means not just 'it works,” but it works well in modern production plants where cleanliness, automation, and compactness matter.

Where is it used?

You'll find vacuum feeders in a wide variety of industries because many of them need to move powders or granules cleanly and efficiently:

- Plastics / extrusion / molding: Feeding granules into injection molding machines or extruders.

- Pharmaceuticals & food: Where hygiene and dust containment are critical.

- Chemicals & materials: Transporting fine powders, pigments, additives in a closed system.

- Building materials, agriculture, metallurgy: For example handling powders, grains, or pellets in larger plants. Indeed, the source notes that the technology 'is now widely used in various light and heavy industries such as chemical engineering, pharmaceuticals, food, metallurgy, building materials, and agriculture and sideline industries.”

Because of the flexibility of piping and the ability to integrate level sensors and automation, it's becoming standard in many plants.

A little story to bring it alive

Picture an artisan bakery that has rolled out a new automated line for flour, cocoa powder, sugar, and other ingredients. Instead of someone lugging sack after sack and dust covering every surface, the bakery installs a vacuum feeder. At the start of the day, sacks of flour are loaded into a central hopper. A vacuum pump kicks in, sucking flour through pipes to individual mixing stations. The operators only need to monitor the system, and they walk past no clouds of flour or dusty corners; the ambient air stays cleaner, the equipment stays cleaner, production is smoother.

In the same way, a chemical plant might use the feeder to move pigment granules from one silo to multiple blending machines, switching the lines automatically depending on which blend is currently running. The feeder makes it far simpler, less messy, and more reliable.

Final thoughts

So when someone asks 'What is the function of the Vacuum Feeder?”, you can say: it's a smart, automated device that uses a negative-pressure (vacuum) system to transport powdery or granular materials in a clean, efficient, enclosed pipeline from one part of the plant to another, depositing them into hoppers or machines with minimal fuss and maximum automation. It takes a task that might have been dusty, manual and messy-and turns it into something quiet, controlled and sleek.

If you're planning a production line and you've got powders, granules, maybe mixing stations, maybe packaging lines, this is a piece of equipment you'll want to consider. And you can check out the example unit at Audop Vacuum Feeder to get a feel for what it looks like and what components it includes.