PVC Automatic Weighting and Conveying System

Overview

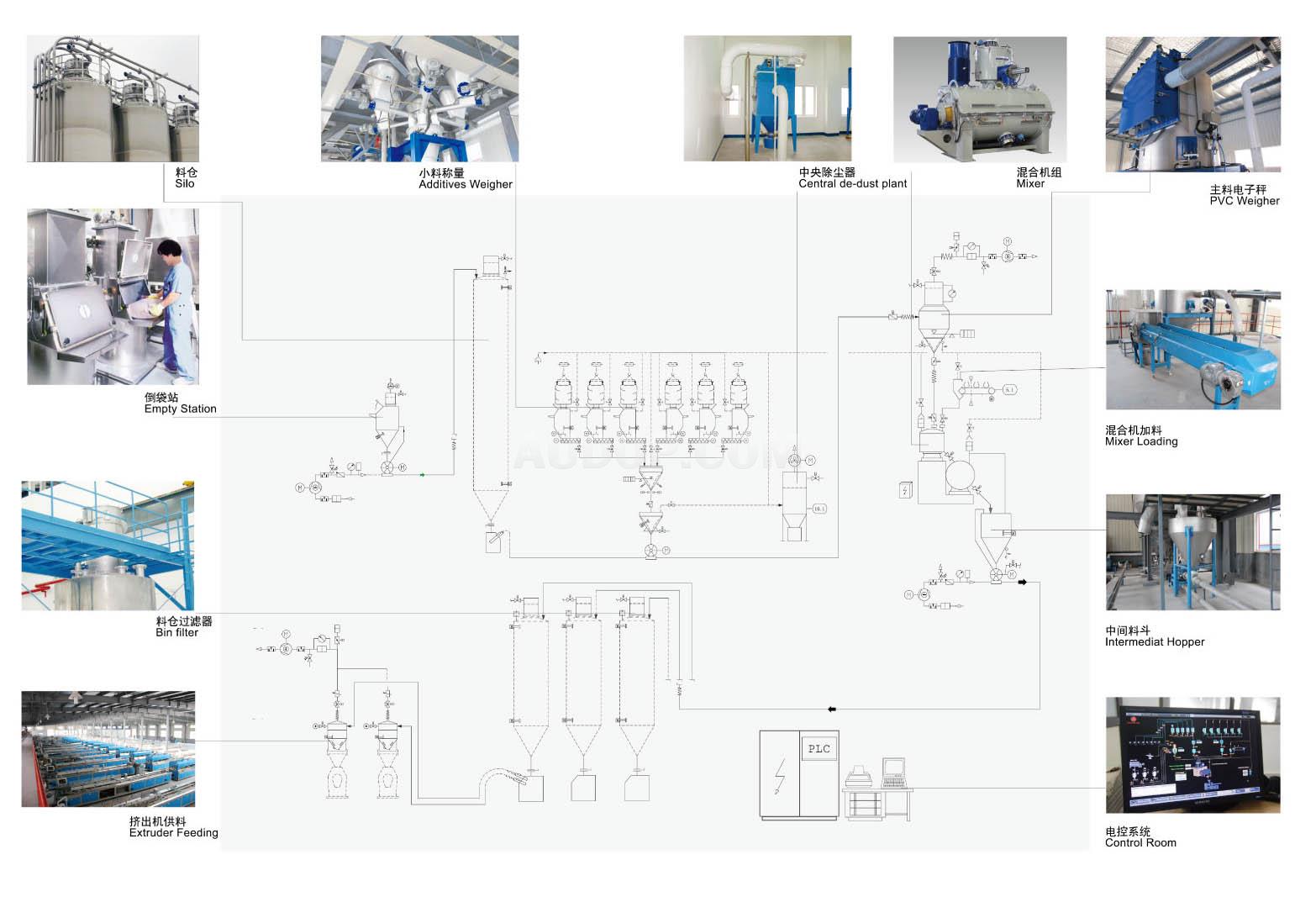

PVC Automatic Compounding Production Line, PVC Powder Centralized Feeding Machine

Mainly used for PVC powder material conveying, negative pressure, positive pressure can be used (dilute phase, dense phase), metering (man material, additives), mixing, centralized storage; according to situation on site, the pipe chain, negative pressure or screw conveying can be used, the material is assigned to each machine hopper. The whole process is centrally controlled by PLC, and centralized monitoring on the host computer.

Mixing system include conveying, dosing and mxing pvc,caco3,other additives to make pipe, sheet, wpc, etc.

Features of PVC Automatic Compounding System

1 Adopting full computer control system which combined engineering control PC machine and PLC, completing overall automatic control, depositing multiple directions, production statistic, random print, dynamic supervision, fault alarm, multiple password protection and so on.

2 Adopting America Toly multiple-threaded pipe metering transducer and control instrument with dynamic precision is ±0.5-1kg

3 Adopting special anti-stick coating and balancing structure metering screw, eliminating the effects which affecting metering precision

4 Adopting special air bag discharging equipment

5 Adopting system pressure balanced centralized dust collecting system

6 Full closed material convey system, preventing secondary pollution and environmental pollution of material

7 Multiple systems model, adapting various workshop conditions

Mainly used for PVC powder material conveying, negative pressure, positive pressure can be used (dilute phase, dense phase), metering (man material, additives), mixing, centralized storage; according to situation on site, the pipe chain, negative pressure or screw conveying can be used, the material is assigned to each machine hopper. The whole process is centrally controlled by PLC, and centralized monitoring on the host computer.

Mixing system include conveying, dosing and mxing pvc,caco3,other additives to make pipe, sheet, wpc, etc.

Features of PVC Automatic Compounding System

1 Adopting full computer control system which combined engineering control PC machine and PLC, completing overall automatic control, depositing multiple directions, production statistic, random print, dynamic supervision, fault alarm, multiple password protection and so on.

2 Adopting America Toly multiple-threaded pipe metering transducer and control instrument with dynamic precision is ±0.5-1kg

3 Adopting special anti-stick coating and balancing structure metering screw, eliminating the effects which affecting metering precision

4 Adopting special air bag discharging equipment

5 Adopting system pressure balanced centralized dust collecting system

6 Full closed material convey system, preventing secondary pollution and environmental pollution of material

7 Multiple systems model, adapting various workshop conditions

Mainly Include Following Process of PVC Powder Centralized Feeding Machine

1) PVC resin weighing system

2) Additives weighing

3) Little material weighing

4) Liquid material feeding

5) Mixing

6) Storing and conveying system

7) Feeding into extruder

1) PVC resin weighing system

2) Additives weighing

3) Little material weighing

4) Liquid material feeding

5) Mixing

6) Storing and conveying system

7) Feeding into extruder

We usually choose international famous brand for electric components. For instance:

PLC: SIEMENS

Inverter: ABB/OMRON

Contactors: SIEMENS

Temperature controller: RKC

Electronic balance: METELER TOLEDO

PLC: SIEMENS

Inverter: ABB/OMRON

Contactors: SIEMENS

Temperature controller: RKC

Electronic balance: METELER TOLEDO

Customers viewing this product may be also interested in:

Powder Centralized Feeding System

- It adopts a full computer control system combining industrial control PC and PLC, which can realize full-process automatic control, store multiple sets of formulas, conduct production statistics, perform random printing, realize real-time dynamic monitoring, give fault alarms, and provide multi-level password protection, etc.;

- It uses a unique anti-sticking coating and a homogenized metering screw to eliminate factors affecting metering accuracy;

- It adopts a unique airbag-type unloading device to completely eliminate the trouble of "bridging" of viscous materials for you;

- It adopts a system pressure-balanced centralized dust removal system to reduce the dust at each leakage point to the minimum;

- The fully enclosed material conveying system prevents secondary pollution of materials and environmental pollution;

- Multiple system combination modes to adapt to various plant conditions.

Granular Material Centralized Feeding System

- It adopts microcomputer centralized automatic control, which can realize 24-hour continuous automatic feeding operation of granular materials. This 24/7 continuous operation capability significantly improves the production efficiency of the factory and is a prominent feature of the granular material centralized feeding system.

- When used in combination with a metering and proportioning machine, the system can realize metering, proportioning and conveying of various materials, featuring accurate metering, fast speed and high metering precision. These advantages make the automatic granular material feeding system suitable for production scenarios that require precise material proportioning.

- The types of raw materials and the combination mode of multi-color materials can be changed as needed, realizing the automation of the coloring process. This feature expands the application scope of the granular material automatic feeding system in the production of multi-variety products.

- When used with a dehumidifier and dryer, the dry air can re-dry the raw materials to prevent the reabsorption of moisture by the dried plastics. This ensures the quality of the raw materials and is an important feature of the granular material centralized feeding system in material moisture control.

- It is equipped with a centralized dust recovery system, which can maintain a clean production workshop and enhance the corporate image. The environmental protection and cleanliness performance of the automatic granular material feeding system meets the requirements of modern enterprise production.

- It can flexibly adjust the feeding volume according to the production capacity of different molding machines, with accurate metering and uniform mixing. This flexibility makes the granular material automatic feeding system adaptable to different production scales and requirements.