Emerging Trends in PVC Fully Automatic Material Blending Systems for the Modern Manufacturer

You always need to make your factory work well and stay ahead. The newest PVC Fully Automatic Material Blending System helps you meet what the market wants. Manufacturers now use smart tools and machines to get the same good quality every time and make changes fast. Spending money on R&D lets you make strong blends that are also very safe. When you look at these new things, think about how they can change the way you make things too.

Key Takeaways

- AI and IoT make PVC blending systems work better. They help fix problems fast and cut downtime by 40%. They also make the product better.

- Automation in blending lines keeps product quality the same. It lowers labor costs and makes things faster. This means fewer mistakes and happier customers.

- Using recycled and eco-friendly materials in PVC blending helps the earth. It also cuts costs and lowers carbon emissions a lot.

- Flexible PVC systems let manufacturers change quickly to meet market needs. They can make different blends fast and waste less.

- Buying advanced blending technology can pay off in one to three years. It saves money on labor and makes the factory safer.

AI and IoT in PVC Fully Automatic Material Blending System

Real-Time Process Optimization

AI and IoT can make your PVC Fully Automatic Material Blending System smarter. These tools let you watch each step as it happens. Smart sensors check things like temperature and pressure. They also watch how materials move. You can spot problems fast and fix them before they get worse.

Many companies use NIR spectroscopy to check blends during production. This tool tells you what is in each batch right away. WARP measurement units check wall thickness and diameter as you work. These tools help your products meet high standards every time.

AI helps with predictive maintenance and finding defects fast. You can find machine problems before they stop your work. Predictive maintenance can cut downtime by up to 40%. Machine learning finds cracks or mixing problems. The system can fix these in seconds. This means better quality and less waste.

Here is how AI and IoT work together in your PVC Fully Automatic Material Blending System:

Integration Aspect | Description |

|---|---|

AI-driven analytics | Predictive maintenance reduces downtime and improves yield. |

Automated production lines | Enhances efficiency and optimizes resin blending, reducing waste. |

Quality-control systems | Ensures consistent product quality and real-time adjustments to processing parameters. |

Supply-chain visibility | Enables demand forecasting and inventory optimization, improving responsiveness to market changes. |

Using these systems can lower your costs by up to 30%. You also get better quality control and fewer recalls. Smart factories help you make new PVC blends faster. You can also react to market changes more easily.

Dynamic Parameter Adjustment with Closed-Loop Systems

Closed-loop systems can make your blending process even better. These systems use AI and IoT to change settings by themselves. If there is a problem, the system changes speed, temperature, or mix right away. You do not have to stop the line or wait for someone to fix it.

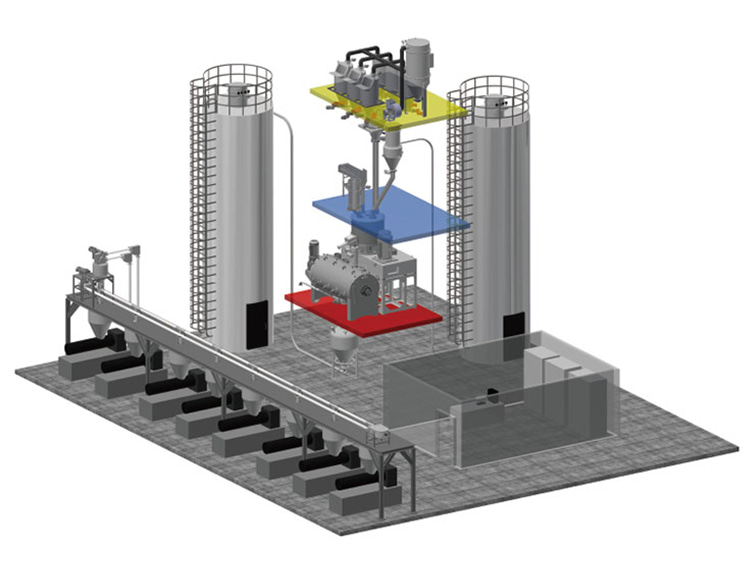

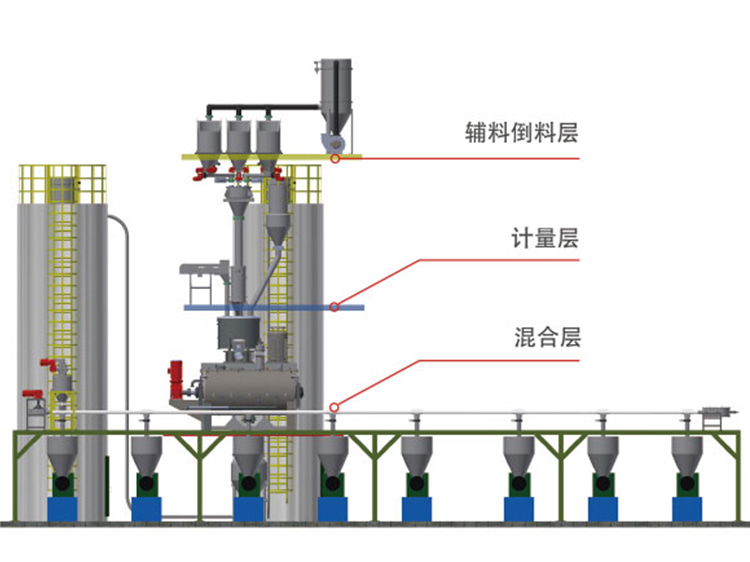

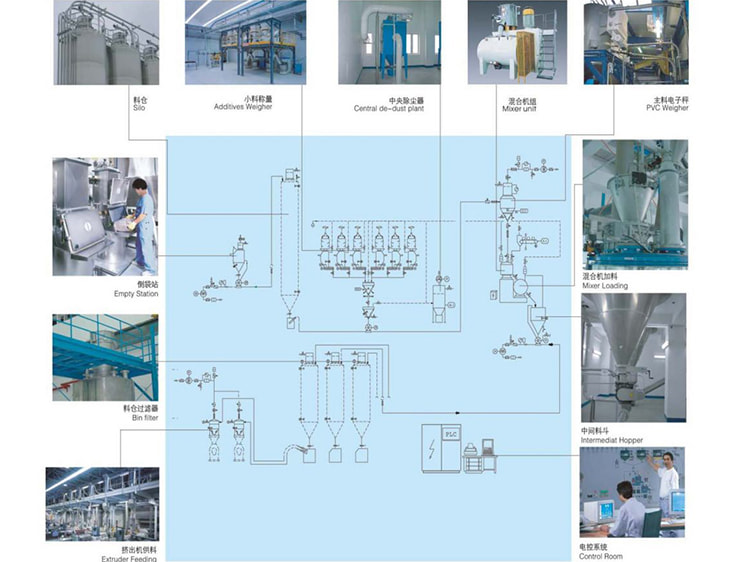

Automatic additive weighing systems help you get the right mix every time. The PVC conveying and mixing system moves and blends materials for the best results. Industrial 4.0 solutions connect all your machines and sensors. This network lets you control everything from one place.

AI-based quality control systems check for defects and fix them fast. Computer vision finds tiny problems people might miss. These systems keep film thickness and adhesion just right. You use less energy and make less waste.

Here are some benefits you get from dynamic parameter adjustment:

- Lower production costs and less waste.

- Better product quality and fewer recalls.

- Faster response to changes in demand.

- Less downtime because of predictive maintenance.

These tools help you stay ahead. Your PVC Fully Automatic Material Blending System becomes more flexible and reliable. You can meet new standards and make better products for your customers.

Automation and Throughput in Blending Lines

Enhanced Consistency and Labor Reduction

Automation helps you make products the same every time. Machines control mixing so each batch is just right. This lowers mistakes and helps customers trust your work. When quality stays the same, your PVC pipes meet the rules. This means fewer recalls and happier customers.

Many factories use blend tower automation and new material delivery systems. These tools help you make more products by working faster. They also make sure each step happens at the best time. You can see the benefits in the table below:

Technology | Benefit |

|---|---|

Blend Tower Automation | Makes more products by working faster and timing steps well. |

Material Delivery | Moves materials on time so batches are not late. |

Automated PVC blending lines are better than old systems in many ways:

Feature | Automated PVC Blending Lines | Traditional Systems |

|---|---|---|

Production Speed | Runs all the time | Works in batches |

Error Rates | Fewer mistakes | More mistakes |

Energy Consumption | Uses much less energy | Uses more energy |

Changeover and Cleaning | Takes less time | Takes more time |

Raw Material Consumption | Uses less material | Uses more material |

Quality of End Product | Always good quality | Quality can change |

Flexible PVC Production Efficiency

You must change to fit what the market wants. Flexible PVC systems let you make different mixes for many jobs. New ideas use artificial intelligence to make work better and improve quality. AI systems in extrusion and calendaring help keep the thickness the same and find problems fast. Real-time data helps you waste less and work faster.

Flexible PVC systems can use many materials and batch sizes. You can pick basic, enhanced, or composite functions to reach your goals:

Function Type | Description |

|---|---|

Basic Functions | Coloring, saving money, and making it softer |

Enhanced Functions | Stops fire, stands up to weather, stops static |

Composite Functions | Coloring + making it softer + lasts longer, filling + stronger + stops fire |

Your PVC Fully Automatic Material Blending System helps you change fast when the market does. You can make great products that fit what people want, with less waste and lower costs.

Sustainability and Lightweight Material Trends

Eco-Friendly and Recycled Inputs

You can make your PVC blending process better for the planet by using recycled and eco-friendly materials. Many factories now add used PVC resin from other products into their blends. This helps you make less waste and use fewer new resources. More companies are also choosing lead-free options, which are safer for people and nature.

Factories use closed-loop cooling to save energy while making products. These systems reuse water and need less power. When you use recycled PVC, you help lower greenhouse gases. Recycling PVC can cut CO2 emissions by up to 92% compared to making new PVC. For every kilogram of recycled PVC, you save about 2 kilograms of CO2. This change helps your factory have a smaller carbon footprint.

You can find recycled PVC in many things today:

- Roofing membranes that last a long time and save energy

- Composite panels for decks and siding

- Insulation materials that keep heat in or out

- Flexible packaging films and containers

- Furniture, home decor, and even cases for electronics

Note: If you pick recycled PVC and energy-saving systems, you can spend less money and help the earth at the same time.

Automotive Sector Demand

There is a big need for lighter materials in the car industry. Car makers want lighter cars because they use less fuel and produce less pollution. About 75% of a car's fuel use comes from its weight. The goal is to make cars 10–15% lighter by using more plastics and composites.

Each new car uses more plastic and composite parts than before. By 2020, the average car had about 25 pounds more of these materials. Factories use advanced PVC blending systems to mix recycled plastics into car parts like inside trims and underbody panels. These systems help you follow strict rules and make cars use less fuel.

Lightweight plastics also help you design cars that drive, speed up, and stop better. You can shape plastics in new ways, so cars can be safer and look cooler. By using more recycled and advanced plastics, you help both the planet and car performance.

Market Drivers and Additives Growth

Expanding Applications in Construction and Automotive

PVC blending systems are used in more places each year. Builders and car makers need these systems for many products. In construction, PVC is found in windows, floors, walls, and sealants. Builders pick PVC because it helps save energy in buildings. Cities are getting bigger, so more buildings are being built. This means more PVC plasticizers are needed. Car makers use PVC for inside and outside car parts. Flexible PVC makes cars lighter and stronger.

More cities and new roads make the need for PVC go up. Countries that are growing build more bridges, homes, and roads. Factories need better blending systems to keep up with this growth. The PVC emulsion market grows fast because people want strong materials for homes and cars.

Note: Saving money and helping the planet also makes people use PVC blending systems more. You can help the earth and spend less by picking these new systems.

Rising Demand for Advanced Additives

There is a big change toward using advanced additives in PVC blending. Makers want to create special blends for different jobs. This leads to new ways to blend and smarter additive technology. Nanomaterials and bio-based additives make PVC stronger, bend more easily, and recycle better.

Here is how advanced additives change the industry:

Aspect | Impact |

|---|---|

Customization | You can meet special needs for every job. |

Sustainability Goals | Bio-based additives and green stabilizers help you reach eco goals. |

Technological Trends | Smart additives make PVC last longer, block UV, and make it easier. |

Regulatory Pressures | You must pick greener additives to follow new rules and please customers. |

Acrylic processing aids help PVC work better. For example, you get stronger layers and higher yield load in 3D-printed parts. These changes help you make better and tougher products.

Tip: Using advanced additives helps you stay ahead and give better choices to your customers.

Regional and Industry-Specific Trends

Emerging Markets Growth

Big changes are happening in PVC blending systems in many places. Asia-Pacific is growing the fastest. Factories there use more fully automatic material blending systems each year. Cities are getting bigger very quickly. They need new buildings, roads, and water pipes. More factories mean people want better PVC products. You see lots of new infrastructure projects in these countries. These things make Asia-Pacific the top region for PVC compounds.

- Asia-Pacific has the fastest growth in PVC blending systems use.

- More people in cities means more buildings and utilities.

- More factories need advanced PVC products.

- New infrastructure projects bring more modern blending technology.

You can learn from what these regions do. When you see their new systems, you can make your own factory better. You stay ahead by watching what works in fast-growing places.

Sector Innovations and Standards

You need to follow industry standards to stay in the game. Many industries want new ideas in PVC blending. Sustainability is very important now. Packaging companies use bio-based PVC to use less fossil fuel. This helps the planet and follows new rules. Construction and car makers care about long life and recycling. Programs like the PVC Stewardship Program make rules for caring for the environment.

Source | Evidence |

|---|---|

Inside Materials – PVC | PVC is used in many industries. Sustainability leads to new blending system designs. |

Exploring PVC: Applications and Essential Considerations | Packaging uses bio-based PVC to cut fossil fuel use. More innovation in sustainability. |

Inside Materials – PVC | PVC lasts a long time and recycles well. Stewardship programs set rules for caring for the earth. |

Standards change how you blend PVC. When you follow these rules, your products are safer and greener. You can also sell in new markets. New blending systems help you meet these standards and build trust with customers.

Tip: Look for new standards in your industry. If you use them early, you can be a leader in quality and sustainability.

Challenges and Opportunities for Manufacturers

Investment and ROI Considerations

When you upgrade to a fully automatic PVC blending system, you have big choices to make. Spending money on new machines can help you earn more later. Most companies get their money back in one to three years. You save money because you need fewer workers and make more products with fewer mistakes. Robots can do jobs that people used to do. This can cut manual labor by half or even more. You might save $100,000 to $200,000 every year. Automation helps you make more products faster. It also helps you waste less, sometimes by up to 30%. Your factory becomes safer, so you might pay less for insurance.

Here is a table that shows important things to think about:

Evidence Type | Details |

|---|---|

Return on Investment (ROI) | You get your money back in one to three years. This happens because you spend less on workers and make more products. |

Labor Cost Reduction | Robots can do many jobs. This can save you a lot of money each year. |

Increased Throughput | Machines help you work faster and waste less. |

Improved Workplace Safety | Fewer accidents mean you pay less for insurance. |

Enhanced Product Quality | Machines help you make better products. Customers are happier. |

You should also think about how you figure out your savings. You save money by using materials again, spending less on additives, and making less scrap. Using energy-saving pumps and dryers can help you get your money back fast. If you turn scrap into resin you can use again, you stop losing money and start making more. Net present value means your investment helps you for a long time.

Compliance and Innovation

You have to follow strict rules about the environment when you use new PVC blending systems. These rules make you lower pollution and change how you work. Meeting these rules can cost a lot and make you change your process. You also need to keep making new things while following the rules.

People want better products and cars that last longer. You make new PVC blends that meet tough rules for safety and pollution. New coatings help your products work better and use less energy. Sometimes, new rules mean you spend more on research and wait longer to sell new products. If the price of materials goes up and down, it can change how much money you make. You also have to compete with other materials.

Factor | Description |

|---|---|

Consumer Demand | People want cars that last and look good. This makes you invent new things. |

Environmental Regulations | Tough rules mean you must use eco-friendly PVC. |

Technological Innovations | New chemistry helps your products work better. |

Regulatory Constraints | Following the rules can cost more and slow you down. |

Raw Material Price Volatility | Prices change, and this affects your profits. |

Market Competition | Other materials and prices make it hard to sell more. |

Environmental Concerns | New ideas must be good for the planet. |

Regulatory Landscape | Agencies make sure you follow the rules for low pollution. |

Technological Adoption Trends | People want products that last, are green, and made by machines. |

Tip: If you buy new technology that follows the rules and helps you invent, you can stay ahead. This helps people trust you and helps your business grow.

You have seen how new trends in PVC blending systems can boost your factory's success. Smart tools, automation, and green practices help you make better products and save money. To stay ahead, you can:

- Read industry news and attend trade shows.

- Test new technology in one part of your plant.

- Ask your team for ideas and feedback.

- Give changes time to work.

- Stay open to new ways of working.

These steps help you lead in 2025 and beyond.

FAQ

What is a PVC fully automatic material blending system?

This system mixes PVC materials by itself. You do not need to do the work by hand. The machine measures and mixes everything. It controls the whole process. You get the same quality every time. It also saves you time.

How does automation improve product quality?

Automation checks every step as it happens. You do not make mistakes as often. Each batch stays the same. Sensors and software help you reach high standards.

Can you use recycled materials in these systems?

Yes, you can use recycled PVC and eco-friendly additives. The system changes its settings for these materials. You help the planet and spend less money.

What should you consider before upgrading your blending system?

Factor | Why It Matters |

|---|---|

Cost | You need to plan your budget. |

Training | Your team learns new things. |

Space | You check if you have room. |

ROI | You see how fast you gain. |

Tip: Ask your supplier to show you how the system works before you buy.