Plastic Shredders and Their Impact on Industrial Recycling

You see plastic waste all the time. Plastic shredders help with this waste in factories and plants. These machines break plastic into tiny pieces. You can recycle and use these pieces again more easily. Shredders help lower pollution and keep things clean. Many industries use shredders to make waste management better and reach sustainability goals.

Key Takeaways

- Plastic shredders cut big plastic items into small pieces. This makes recycling simple and quick. Using shredders helps companies save money. They do this by making less waste and lowering trash costs. Shredders help the circular economy. They get plastic waste ready for recycling. This keeps plastic out of landfills. There are many kinds of shredders. You should pick one for your plastic type and waste amount. Recycling shredded plastic can make money. Many companies want recycled stuff for new products.

Role of Plastic Shredders in Recycling

Waste Processing Functions

Plastic shredders help people deal with plastic waste. These machines cut big plastic items into small pieces. Small pieces are easier to move and store. Shredders make recycling faster and simpler.

You can watch shredders turn hard plastic into small bits.

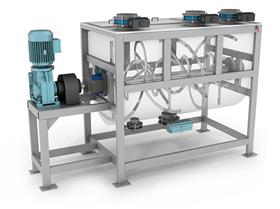

A double shaft shredder has two spinning shafts. The shafts spin in different ways. Each shaft has sharp blades. The blades slice through tough plastics. This design helps you break strong materials easily.

Here are some ways plastic shredders help with waste:

- They make plastic waste smaller, so it is easy to move and store.

- Shredded plastic can be sorted fast, which helps recycling plants work well.

- Small pieces help recover useful materials and protect the environment.

Supporting the Circular Economy

Plastic shredders help people support the circular economy. When you shred plastic waste, you get it ready for new uses. You can recycle these pieces into new things. This keeps plastic out of landfills.

Many industries use shredders to control plastic waste. In car factories, you can break big plastic parts and recycle them. Construction companies use shredders for leftover plastic. This makes it easy to move and reuse.

Shredders help you change waste into things you can use again.

In many jobs, plastic shredders make recycling simple. You help keep plastic out of landfills and protect nature. By using shredders, you help the planet and keep useful materials in use.

Industrial Applications of Plastic Shredders

Manufacturing and Construction

Factories and building sites have lots of plastic waste. Plastic shredders help manage this waste. They break down leftover plastic from products and building materials. Shredding makes plastic easier to move and recycle. It also keeps work areas clean and safe. Many companies use shredders for plastic pipes, sheets, and packaging. This saves money and helps the environment.

Laboratories and Pharmaceuticals

Labs and pharmaceutical companies must handle plastic waste with care. Plastic shredders here use strong blades or grinders to destroy plastic items. This keeps people safe and follows waste disposal rules. Shredded plastic goes into secure bins. You can recycle it or throw it away safely. These machines help stop pollution and keep dangerous materials out of nature.

Note: Pharmaceutical shredders meet strict industry rules. They help you follow the Bio-Medical Waste Management Rules, 2016. These rules say you must handle and throw away biomedical plastic waste the right way. Using shredders in labs or pharmacies protects people and nature.

- The Bio-Medical Waste Management Rules, 2016, tell you how to shred and dispose of pharmaceutical plastics.

- You must handle and dispose of all biomedical plastic waste properly.

- All labs and pharmaceutical companies must adhere to these rules to ensure everyone's safety.

Catering and Packaging

Catering and packaging use lots of plastic. Plastic shredders help with soft plastics like films, bags, and wraps. These light materials can block recycling machines. Special shredders cut them into small pieces. You can then recycle or reuse them.

- You shred flexible packaging like plastic films, bags, and wraps.

- Shredders make waste smaller, so it is easy to store and move.

- You fill containers better and need fewer landfill trips.

- Shredding helps send less waste to landfills and saves space.

Automotive Industry

Cars have many plastic parts. Plastic shredders help recycle these parts. You can shred bumpers, inside panels, and strong plastics. This makes sorting and recycling easy.

Component Type | Examples |

|---|---|

Plastic Parts | Bumpers, Interior Panels |

Composite Materials | Reinforced Plastics, Rubber |

You also recycle different plastics in cars, like:

- Polypropylene (PP)

- Polyurethane (PU)

- Polyvinyl Chloride (PVC)

- Acrylonitrile Butadiene Styrene (ABS)

Using shredders in the automotive industry helps cut waste and support recycling. You keep useful materials in use and help protect the planet.

Benefits of Plastic Shredders

Cost and Waste Reduction

Plastic shredders can help your business save money. These machines make plastic waste smaller. When you shred plastic, the waste can shrink by 40% to 80%. This means you pay less to get rid of your trash. For example, if you have 100 cubic yards of waste and pay $50 for each yard, shredding can save you $3,500 every month if you cut the waste by 70%. You also need fewer trash pickups, so you pay less for hauling. Workers spend less time moving waste, so you save on labor.

- Shredding can make waste up to 80% smaller.

- Fewer pickups mean you pay less for trucks.

- Workers do not need to spend as much time on waste.

Your waste is easier to move and store. This keeps your work area clean and safe.

Benefit | Description |

|---|---|

Reduces transportation costs | Decreases volume, allowing for more efficient transport. |

Improves landfill management | Allows for more compacted waste, optimizing landfill space. |

Boosts recycling efficiency | Pre-processes materials, making recycling easier. |

Increases safety | Eliminates sharp or hazardous components in waste. |

Volume reduction statistic | Shredding can reduce waste volume by up to 60%. |

Tip: Shredding plastic lets you fit more waste in each container. You need fewer trips to the landfill.

Environmental Impact

Plastic shredders are good for the environment. Shredding makes it easier to recycle plastic. Less plastic ends up in landfills. Recycling also uses less energy than making new plastic. This means you make fewer greenhouse gases. When you recycle, you save oil and gas.

Environmental Benefit | Description |

|---|---|

Reduction in Landfill Waste | Efficient shredding increases recycling rates, thus decreasing landfill waste. |

Lower Greenhouse Gas Emissions | Recycling with shredders results in lower emissions compared to producing new plastics. |

Conservation of Natural Resources | Recycling saves petroleum and other resources needed for new plastic production. |

Lower Carbon Footprint | Recycling plastics uses less energy than new production, leading to reduced greenhouse gas emissions. |

Shredders also help your company follow the rules. Shredded plastic is easier to sort and recycle. This helps you follow the law and keeps your business safe.

Benefit | Description |

|---|---|

Efficient waste reduction | Shredder machines reduce the volume of materials, making them easier to handle and transport. |

Improved recycling rates | Shredded materials are easier to sort and separate, leading to higher-quality recycled materials. |

Environmental benefits | Reducing waste volume and increasing recycling rates positively impact the environment. |

Note: Using shredders helps your company reach its green goals. It shows you care about the planet.

Revenue from Recycled Plastics

You can make money by selling recycled plastic. Many companies want to buy recycled materials. Shredding plastic gets it ready for recycling. This makes your waste worth more. You can sell shredded plastic to other companies. They use it to make new things.

- More people want to help the environment, so more people want recycled plastic.

- Governments make rules that support recycling.

- Companies want to use more recycled materials.

You can turn your waste into money. Using plastic shredders helps your business and the planet.

Choosing the Right Plastic Shredder

Shredder Types Overview

There are different types of plastic shredders. Each one works best for certain jobs. The table below lists the main types and what they do:

Type of Shredder | Description |

|---|---|

Hammer Mills | Break materials apart with hammers in a drum. |

Granulators | Recycle plastic from making products, like thermoforming. |

Chippers | Use fast knives to make flakes and chips. |

Grinders | Crush materials into small pieces using pressure. |

Shear Shredders | Cut materials with spinning blades and sharp knives. |

All-purpose Shredders | Big, slow machines with strong force for recycling and breaking things. |

Tip: Pick the shredder that matches your plastic type and how much waste you have.

Single-shaft shredders are good for small jobs and use less power. Dual-shaft shredders are better for big jobs and can shred more at once. Dual-shaft shredders need more care because they have extra moving parts.

Selection Factors

When you choose a plastic shredder, think about some key things. Here is a list to help you decide:

- Capacity & Throughput: See how much the shredder can handle each hour.

- Material Compatibility: Make sure it works with your plastics.

- Motor Power & Efficiency: Find a strong motor that saves energy.

- Build Quality: Pick shredders with tough frames and sharp blades.

- Cut Size Adjustability: Choose machines that let you change the size of pieces.

- Safety Features: Look for guards and emergency buttons to keep workers safe.

- Maintenance Access: Easy access helps you fix problems fast.

- Warranty and Support: Good support means less time fixing things.

- Additional Options: Think about noise and if you need special voltages.

Factor | Description |

|---|---|

Material Type | Hard and thick plastics need strong shredders. |

Volume Capacity | How much waste you have each day or hour matters. |

Shredding Output Size | Pick the right size for recycling or throwing away. |

Note: Picking the right shredder helps you recycle more, spend less, and keep your workplace safe.

Plastic shredders turn plastic waste into even flakes. This makes recycling quicker and more exact. When you pick the right shredder, you work faster and get cleaner materials. You can use shredders for many kinds of plastics. This helps your business handle waste better. New shredders also save energy and can be changed for different jobs. If you choose the best machine, you help keep the earth clean. You also get ready for new ways to recycle in the future.

FAQ

What types of plastics can you shred with a plastic shredder?

You can shred most common plastics, like PET, HDPE, PVC, and polypropylene. Some shredders handle tougher plastics or mixed materials. Always check your shredder's manual for a full list.

How often should you maintain your plastic shredder?

You should check your shredder every week. Clean the blades and remove stuck pieces. Oil moving parts as needed. Regular care keeps your machine safe and working well.

Is it safe to use a plastic shredder?

Yes, plastic shredders have safety features like guards and emergency stops. Always follow the instructions. Wear gloves and safety glasses. Never put your hands near the blades.

Can you make money by recycling shredded plastic?

Yes! Many companies buy shredded plastic to make new products. You can sell your shredded plastic to recycling centers or manufacturers. This helps you earn extra income and supports recycling.

Plastic Bottle Recycling Equipment: The Complete Guide for 2026

Learn how 2026 recycling technology transforms PET bottles into premium rPET using AI sorting,energy-smart washing,and modern pelletizing systems.

Important Guidelines for Operating and Maintaining Vertical Mixer Dryer

Learn essential tips for safely operating and maintaining your vertical mixer dryer.Improve drying efficiency and extend machine life with the Audop Vertical Mixer Dryer.

Can an Additives Automatic Weighing Machine Be Integrated with Other Equipment

Discover how the Audop Addtives Automatic Weighing Machine integrates seamlessly with mixers,feeders,and conveying systems to improve efficiency and precision.