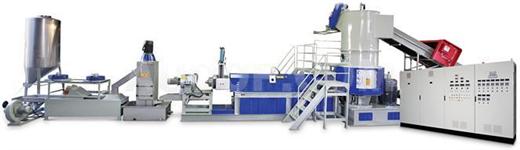

Plastic Recycling Machine

- Constant high pellet quality.

- Saving. Less power consumption cost per kilogram, reduced floor space occupation and operator attendance.

- High efficiency and high throughput. Combines three functions in one, such as shredding, extruding and palletizing. Many materials can be processed directly without need of upstream pre-shredding, resulting in a dramtic reduction in operational costs.

Overview

Plastic Recycling Machine, plastic recycling system, plastic recycling plant

- Applicable Materials: PP, HDPE, LDPE, LLDPE, TPV, EVA, ABS, and PS, etc.

- Material Shapes: Film, bag, scrap, flake, etc

- Material Types: Film(rolls,loose,bundled), agricultural film waste, printed LDPE film, Woven bag, washed post-consumer waste,foamed plastics(EPS) and raffia, etc.

- Alias: Plastic recycling equipment, plastic pelletizer, plastic granulating machine, plastic pelletizing line, plastic granulating line, plastic pelletizing system, plastic recycling plant

Plastic Recycling Machine is State-of-the-art technology for high-value processing of plastic recycling. It is used for making the clean materials or washed material into regular uniform pellets(granules), it also is known as the plastic recycling system, film recycling machine, film recycling line, film pelletizing machine, film pelletizing line, granulating line, granulation machine, waste plastic recycling machine, recycling machine, etc.

This plastic recycling machine is consisted of a conveyor, agglomerator, extruder, hydraulic screen changer, cutting system, centrifugal dewater machine, air sending system, and silo. Metal detector, roll feeder, degassing system, chiller, vibrating screener are optional devices, it may be provided depends on the property of the material.

Factory view:

Technical Parameters

Technical Parameters

| Model | ADP-FR85 | ADP-FR100 | ADP-FR120 | ADP-FR140 | ADP-FR160 | ADP-FR180 |

|---|---|---|---|---|---|---|

| Applicable Materials | PP / HDPE / LDPE / LLDPE / EVA / ABS / PS | |||||

| Actual throughput per hour | PP=200kg HDPE=250kg LDPE=300kg | PP=300kg HDPE=350kg LDPE=350kg | PP=380kg HDPE=420kg LDPE=450kg | PP=480kg HDPE=520kg LDPE=550kg | PP=650kg HDPE=800kg LDPE=750kg | PP=750kg HDPE=900kg LDPE=960kg |

| METAL DETECTOR | Optional | |||||

| BELT CONVEYOR | ||||||

| Type | Rubber belt conveyor | |||||

| Feed speed | 0.05m/sec. | |||||

| Drive motor | 1.1kw | 1.1kw | 1.5kw | 2.2kw | 2.2kw | 3kw |

| ROLL FEEDER | Optional | |||||

| AGGLOMERATOR | ||||||

| Drive motor | 45kw | 55kw | 75kw | 90kw | 110kw | 132kw |

| EXTRUDER | ||||||

| Main drive motor | 75kw AC+INV | 90kw AC+INV | 132kw AC+INV | 160kw AC+INV | 200kw AC+INV | 250kw AC+INV |

| Type | With or without degassing system (venting hole) | |||||

| Screw diameter (mm) | Ø85mm | Ø100mm | Ø120mm | Ø140mm | Ø160mm | Ø180mm |

| L/D ratio | 34:1 | 34:1 | 34:1 | 33:1 | 33:1 | 33:1 |

| Screw material | 38CrMoAlA, nitrided and chrome plated | |||||

| Barrel material | 38CrMoAlA, precision ground and nitrided | |||||

| Screw speed (rpm) | 0-180 | 0-170 | 0-150 | 0-130 | 0-130 | 0-120 |

| Barrel heater | 28kw | 33kw | 45kw | 55kw | 60kw | 72kw |

| Barrel cooling | Air cooling | |||||

| Cooling power | 3.5kw | 4kw | 4.5kw | 5kw | 5.5kw | 6kw |

| SCREEN CHANGER & DIE | ||||||

| Type | Single-plate hydraulic screen changer with double working position | |||||

| Heater | 5.5kw | 6.4kw | 7kw | 7.5kw | 8kw | 10kw |

| Filter screener diameter | Ø120mm | Ø180mm | Ø250mm | Ø300mm | Ø350mm | Ø400mm |

| PELLETIZER | ||||||

| Pelletizing type | Die face water ring pelletiser for PE, underwater pelletiser for PP | |||||

| Pelletizing motor | 3-5 HP AC+INV | |||||

| Die heater | 3kw | 3.2kw | 3.8kw | 4.8kw | 6kw | 8kw |

| Pelletizing hole dia. | Hole dia. and numbers depend on material and palletizing type | |||||

| COOLING DEVICE | ||||||

| Type | Water cooling | |||||

| Water pump | 3kw | |||||

| Chiller | Optional | |||||

| DEWATERING&SORTING | ||||||

| Dewatering motor | 5.5kw | |||||

| VIBRATING SCREENER | Optional | |||||

| TRANSPORT&STORAGE | ||||||

| Blowing motor | 2.2kw | 2.2kw | 3kw | 4kw | 4kw | 5.5kw |

| Silo capacity | 1M3 | |||||

| Model | ADP-FR85 | ADP-FR100 | ADP-FR120 | ADP-FR140 | ADP-FR160 | ADP-FR180 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Water-ring Pelletizing System

Water-ring pelletizing systems(also called water ring pelletizers) are suitable for processing a wide range of polymers, unfilled or filled, in reclaim, masterbatch and general compounding.

- Simple start-up: no strands to handle, no water-flow timing concerns.

- Hot die-face cutting: insensitive to melt flow interruptions.

- Continuous production: high productivity.

- Exclusive flex-blade design: no sensitive knife adjustments, extended service life.

- Hot cutting in air: saves power vs. cold strand or underwater cutting.

Waste PlasticPP PE Film Washing Recycling Machine

PP PE Plastic Film Washing Recycling Line(also called Plastic Film and Bag Washing Plant) are suitable for processing a wide range of waste films, packing films, agricultural waste films, bags, woven bags, and so on, it is an ideal recycling system for all kinds of material made from PE,HDPE,LDPE,PP,BOPP, such as tables, chairs, and so on.

- Simple start-up: it is made up by many seperately machines, running from end to beginning one by one

- High Quality: European and Janpanese technologies are adopted.

- Continuous production: high productivity.

- Years of experience, mature technology,excellent after-sale service,long terms of cooperation.