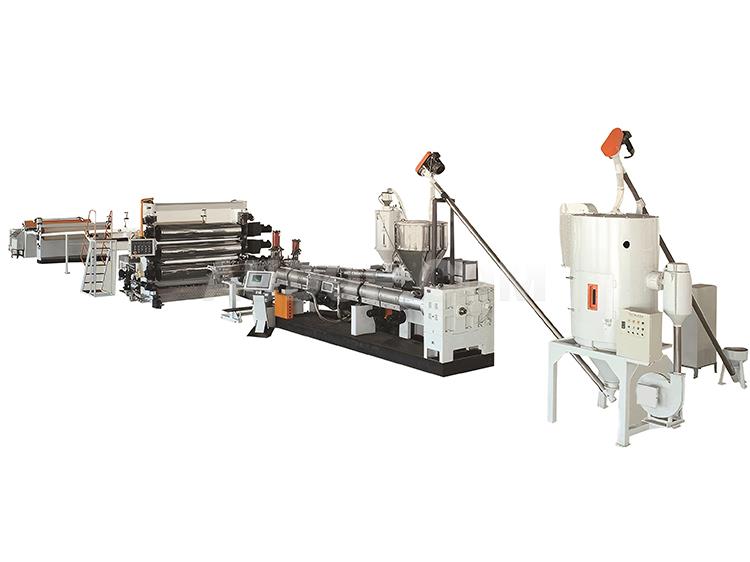

ABS PMMA HIPS GPPS Sheet Production Line

- Continuous and efficient: Fully automated continuous production process, from raw materials to finished products, without any interruption, with high production capacity.

- Flexible customization: The thickness and width of the sheet can be adjusted. It supports multi-layer co-extrusion or functional (fire-retardant, anti-aging) production.

- Intelligent integration: Integrates multiple modules such as raw material processing, extrusion, and shaping. Through PLC or online detection (laser thickness measurement, defect detection), parameter linkage and precise quality control are achieved.

- Environmentally controlled: Equipped with exhaust / waste gas treatment to reduce pollution. Edge materials can be recycled and reused. Cooling system uses closed-loop water circulation.

- Stable quality: Zone temperature control and vacuum shaping ensure the flatness and smoothness of the plates, with minimal errors.

Overview

ABS/PMMA Composite Sanitary Ware Panel: It is made by co-extrusion of PMMA and ABS. It retains the rigidity and luster characteristics of acrylic panels, while also taking into account the impact resistance advantages of ABS panels. It has good molding performance, high temperature resistance, low temperature resistance, wear resistance, corrosion resistance, and excellent mechanical processing performance. It is used for bathroom products such as bathtubs, shower rooms, steam rooms, and washbasins.

ABS, HIPS/GPPS refrigerator panel production line: It is divided into ABS panels, ABS non-fluorine panels, ABS antibacterial panels, HIPS high-gloss composite panels, and HIPS anti-141b composite panels. It has extremely strong low-temperature toughness, impact resistance, chemical stability and other excellent properties. It is mainly used for refrigerator and freezer door shells, inner shells, drawers, drainage systems, water dispensers, etc.

ABS automotive (bag) panels: include textured panels, matte textured panels, flame-retardant textured panels, etc. They possess excellent thermoplastic properties, flame-retardant characteristics and high impact resistance. Applications: for car and bus roofs, instrument panels; seat backs, door panels, window frames, motorcycle shells, various trolley bags, luggage cases, leisure bags and other luggage.

ABS thick sheet: ABS sheet is a new type of material in the sheet industry. Its full name is Acrylonitrile-Butadiene-Styrene sheet. The English name is Acrylonitrile-butadiene-styrene, and it is currently the polymer with the largest production volume and the most widespread application. It integrates the various properties of PS, SAN, and BS, possessing excellent mechanical properties with a balance of toughness, hardness, and rigidity. ABS sheet has excellent impact strength, good dimensional stability, good dyeability, good molding processing and mechanical processing, high mechanical strength, high rigidity, low water absorption, good corrosion resistance, simple connection, non-toxic and odorless, and excellent chemical and electrical insulation properties. It can withstand heat without deformation, and also has high impact toughness at low temperatures. It is also a hard material that is not easily scratched or deformed. It has low water absorption and high dimensional stability. Common ABS sheets are not very white, but they have excellent toughness and can be cut using a shearing machine or molded with a mold. Product applications: food industry parts, architectural models, hand model making, photoelectric industrial components, refrigerator refrigeration industry, electronic and electrical fields, pharmaceutical industry, etc.

Main Mechanical Components:

Extrusion System: As the core part of the plastic production line, it is usually composed of multiple single-screw extruders.According to the characteristics of different materials, it is equipped with a specially designed screw structure and PLC temperature control system to ensure stable plastic plasticization process and constant output.Modern extrusion systems are also equipped with hydraulic screen changers, which can realize non-stop screen changing and greatly improve production efficiency.

Mold System: It adopts a coat hanger sheet die design and can be equipped with a melt gear pump to realize quantitative and constant-pressure material delivery, ensuring stable melt extrusion and uniform product thickness.This design can ensure the produced sheets have consistent thickness and smooth, flat surfaces.

Forming System: It is mainly composed of a vertical or inclined three-roll calender, equipped with a roll temperature controller and a high-precision gap adjustment sensor, and is equipped with an emergency stop function to ensure operational safety.The rolls of the three-roll calender are usually made of 42CrMo material, and their surfaces are treated with mirror polishing to achieve an ultra-mirror finish with Ra ≤ 0.015μm.

Cooling And Conveying System: It is equipped with a high-precision alumina roll conveying device and can be equipped with slitting and trimming devices as required.The cooling system ensures the sheets are cooled gradually at a controlled speed to avoid deformation and internal stress.

Traction And Cutting System: Rubber roll traction ensures stable plate conveying, and its speed is synchronized with the three rolls.The transverse cutting machine adopts cylinder clamping and follow-up cutting methods, and is matched with alloy saw blades and dust suction devices to achieve precise cutting.

Stacking System: Modern plastic production lines can be equipped with on-line intelligent robotic arm automatic stacking systems to realize fully automatic grabbing, transportation and stacking.Its working process includes: robotic arm origin → grabbing signal → robotic arm descending → vacuum grabbing → robotic arm ascending → entering the stacking area → robotic arm descending → releasing the plate → robotic arm returning to the origin.

Control System: It adopts a PLC control system, equipped with a human-machine interaction touch screen, which can store process parameters and realize automatic operation, real-time monitoring and fault diagnosis.Advanced systems can also record relevant data of each batching process, such as material type, weight, mixing time, etc., to facilitate quality traceability and production management.

After Service :

We offer comprehensive after-sales services, including equipment installation and commissioning, operator training, regular maintenance and repair, and fault troubleshooting. Our professional team will ensure the normal operation of the equipment, promptly solve the problems encountered by customers during use, and provide a strong guarantee for their production. At the same time, we also provide old system renovation services to meet the increasingly strict dust control and new process control requirements.

Technical Parameters

Technical Parameters

| Model | Single Screw AS120/AS65/AS45 | Single Screw AS150/AS90 | Single Screw AS180/AS105 | Parallel Twin Screws AP75/ Single Screw AS90 |

Applicable Raw Materials | PMMA;ABS;GPPS;HIPS | PMMA;ABS;GPPS;HIPS | PMMA;ABS;GPPS;HIPS | PMMA;ABS;GPPS;HIPS |

| Product Structure | A/B/C/B/A;A/B/C;A | A/B/A;A/B;A | A/B/A;A/B;A | A/B/A;A/B;A |

| Product Thickness(mm) | 2-8 | 1-6 | 2-8 | 2-8 |

| Product Width(mm) | 2100 | 1700 | 2100 | 2100 |

| Output(KG/H) | 600 | 650 | 800 | 800 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

PC Sheet Production Line

- Extruder: Special-designed screw, temperature control system, ensuring stable plasticizing performance and extrusion efficiency.

- Mold: Alloy mold lip and adjustable flow-blocking block, providing uniform pressure.

- Vacuum shaping table: The display of the thermal convection system is interwoven, with a special cooling shaping design, ensuring accurate shaping and cooling.

- Electrical control system: Utilizes PLC control parameters and has optimized the operation characteristics.

PC PP PE PVC ASA Sheet Extrusion Production Line

- The rack-type flatbed machine head is equipped with a pneumatically-operated opening and closing forming mold, a flexible and safe lifting mechanism, which ensures more reliable forming, enables continuous production, and makes thickness adjustment extremely convenient.

- Using rubber traction rollers that match the waveform, the traction is extremely smooth. The roller spacing adjustment device is convenient and quick, and it has the ability to handle various situations on-site.

- The meticulously designed cutting method, with the automatic inclined-edge cutting, results in a more precise and neat cut. It can also be automatically cut to the desired length as per requirements, highlighting the people-oriented design concept.

- By using a special technical formula, it can be co-extruded as ASA. It can withstand outdoor atmospheric exposure and has excellent heat insulation properties. In hot summer, it can provide a more comfortable environment than metal roofing.

PP PE ABS PVDF PVC Thick Plate Extrusion Line

- High-Efficiency Production & Thick Sheet Adaptability

• Enables continuous extrusion of ultra-thick sheets with optimized energy efficiency ratios.ultra

• Optional tandem extrusion technology supports specialized sheet processing (e.g., glass fiber-reinforced sheets). - Precision Process Control

• Intelligent temperature control and pressure feedback systems ensure uniform thickness, smooth surfaces, and minimal material waste.

• A multi-stage flow channel design combined with an adjustable three-roll calibration system enhances dimensional accuracy. multi-stage flow. - Durability & Full Automation

• Core components are made of corrosion-resistant materials and coated with advanced technology to extend equipment service life.

• Integrated rapid mesh changing, automatic cutting, and stacking systems reduce manual intervention and achieve full automation. - Flexible Configuration & Scalability

• Supports vertical/inclined rolling machines and coil/sheet winding devices for diverse production scenarios.

• Scalable multi-layer co-extrusion and laminating functions meet special requirements, including high barrier performance and weather resistance.

- High-Efficiency Production & Thick Sheet Adaptability

PVC Soft Curtain Production Line

- The screw is designed with special mixing function and high plasticizing capacity.

- The hanger - type die adopts a special double-throttling design, which allows for more precise adjustment of the sheet thickness.

- With a temperature control accuracy of ±1?, it can accurately control the plasticizing process, as well as the thickness and flatness of the product.

- The three-roll calender can be used in horizontal, vertical or 45-degree inclined modes, and supports free lifting operation.

- The thickness of the sheet is controlled by both screw adjustment and bidirectional adjustment of the pressure wheel.