How to Choose a Volumetric Feeder

Choosing the right volumetric feeder is essential for achieving accurate and consistent material dosing in any production process. This guide explains how to select between single and double screw volumetric feeders, helping you match the right equipment to your material properties and application needs. Learn how Audop's volumetric feeders deliver precision, reliability, and efficiency across various industries.

When it comes to material feeding in industrial production, precision and consistency make all the difference. Whether you're handling powders, granules, or small pellets, choosing the right volumetric feeder can dramatically affect your process efficiency, product quality, and maintenance costs. But with several types of feeders available, how do you decide which one is the best fit for your application? Let's take a closer look at the key factors - and the differences between single screw and double screw volumetric feeders.

What is a Volumetric Feeder?

A volumetric feeder is a device designed to deliver a consistent volume of material over a specific time. It doesn't weigh the material (that's what gravimetric feeders do), but instead meters it based on volume, using controlled screw rotation to ensure uniform discharge. This makes it a cost-effective and reliable solution for many industries such as plastics, chemicals, food, and pharmaceuticals.

Choosing the Right Feeder for Your Material

The main rule of thumb when choosing a volumetric feeder is: the more difficult your material is to handle, the more precise your feeding mechanism needs to be. Materials that are free-flowing and dry are usually easier to feed than sticky, cohesive, or irregular materials.

This brings us to the two main types of volumetric feeders: single screw and double screw.

Single Screw Volumetric Feeder – Simple and Reliable

If your production involves uniform, free-flowing materials such as plastic granules, sugar, or salt, a single screw feeder is often the ideal choice. It features a single rotating screw that moves the material forward in a smooth and predictable way.

The Audop Single Screw Volumetric Feeder is a great example of this design. It's compact, easy to clean, and suitable for continuous or batch feeding. Thanks to its straightforward structure, it requires minimal maintenance and offers stable feeding for dry, non-cohesive materials.

Advantages:

- Excellent for free-flowing materials

- Easy operation and maintenance

- Cost-effective and efficient

However, for materials that are sticky, fluffy, or tend to clump together, a single screw feeder might not provide the level of consistency you need. That's where the double screw version shines.

Double Screw Volumetric Feeder – For Complex Materials

When dealing with powders or materials that have poor flow characteristics, the double screw feeder becomes the go-to solution. Equipped with two intermeshing screws, this design prevents material bridging and ensures smoother, more consistent feeding.

The Audop Double Screw Volumetric Feeder is engineered to handle challenging materials with precision. Its twin screws rotate together to agitate and convey the material evenly, maintaining a uniform output even for sticky or cohesive substances like titanium dioxide, carbon black, or flour.

Advantages:

- Handles poor-flowing or sticky materials

- Provides better uniformity and stability

- Reduces clogging and material buildup

While it's slightly more complex than a single screw feeder, its improved control and flexibility often justify the investment for demanding applications.

Other Factors to Consider

Beyond the screw type, a few more aspects deserve attention before making your final choice:

- Feed rate requirements: Determine how much material you need per minute or hour.

- Material characteristics: Density, particle size, and moisture content can all affect feeder performance.

- Ease of cleaning: For industries like food or pharma, quick disassembly and sanitation are critical.

- Integration: Make sure the feeder can work seamlessly with upstream and downstream equipment.

Final Thoughts

Selecting the right volumetric feeder is about understanding your material and process requirements. If your materials flow easily and you prioritize simplicity, a single screw feeder might be your best bet. If you deal with powders that are difficult to handle, the double screw feeder provides the consistency and control you need.

Whether you choose the Audop Single Screw Volumetric Feeder for simplicity or the Audop Double Screw Volumetric Feeder for versatility, you can count on precision, durability, and reliable performance that keeps your production line running smoothly.

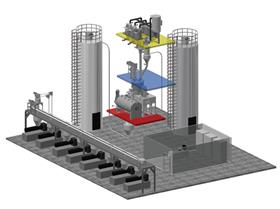

The Five Major Advantages of Audop PVC Fully Automatic Material Blending System

Audop PVC Fully Automatic Material Blending System delivers precise weighing,dust-free conveying,and uniform high-speed mixing for consistent,efficient,and automated PVC compound production.

How to Maintain Your Plastic Granulator Machine for Longer Life

Learn how to extend the life of your plastic granulator machine with practical maintenance tips.Discover how to care for the screw and barrel,gearbox and lubrication system,and heating and cooling system.

2026 Guide for Selecting Plastic Powder Pellet Loading Equipment

Learn how dust-free stations,ton bag unloading,automatic bag openers,and closed systems improve cleanliness,safety,and efficiency in 2026 plastic material handling.

What Are the Differences Between Ultrasonic Rotary Vibrating Sifter and Ordinary Vibration Sifter

Discover the key differences between ultrasonic rotary vibrating sifters and ordinary vibration sifters.Learn how the Audop Ultrasonic Rotary Vibrating Sifter improves screening precision,prevents mesh clogging,and enhances production efficiency for fine.

Why Are High-Speed Mixers So Widely Used

Discover why high-speed mixers are essential in modern manufacturing.Learn how the Audop High Speed Mixing Machine delivers fast,consistent,and efficient performance across plastics,chemicals,and food industries.