How to Maintain Your Plastic Granulator Machine for Longer Life

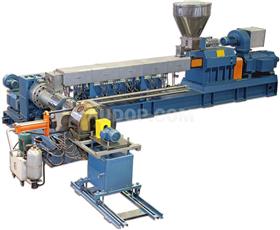

Looking for a durable and efficient way to recycle or compound your plastic materials? The Audop plastic granulator is designed to deliver high-performance granulation with long-lasting reliability. Built with precision-engineered screws, a robust gearbox, and an advanced heating and cooling system, it ensures smooth operation and consistent granule quality. With proper maintenance and regular inspection, your granulator can achieve years of stable performance, reduced downtime, and excellent energy efficiency-making it an ideal choice for both small-scale and industrial plastic processing applications.

A plastic granulator is like the heartbeat of a recycling or compounding line - tirelessly cutting, melting, and forming plastic materials day after day. But just like any hardworking machine, it needs a little care and attention to keep running smoothly. Proper maintenance not only prevents costly breakdowns but also ensures consistent output and energy efficiency over the long term.

Whether you own a small lab-scale unit or a full industrial setup such as the Audop plastic granulator, keeping it in top condition doesn't have to be complicated. Here are the key areas to focus on for a longer machine life.

1. Screw and Barrel: The Core of Performance

The screw and barrel are the heart of your granulator system. Over time, they endure high pressure, friction, and temperature-especially when processing abrasive or filled materials. Regular inspection is essential.

- Clean after each batch: Residual plastic can harden and cause wear or clogging. Use proper cleaning compounds instead of metal tools to avoid scratching the barrel.

- Check for wear patterns: Uneven wear may indicate alignment issues or contaminated feedstock.

- Avoid Idling and Cold Starts: Never start the main unit before the barrel reaches its preset temperature, as this causes excessive screw torque and severe damage. Additionally, minimize prolonged screw idling without material.

- Apply the right lubrication: If your design requires grease on the screw shaft or bearings, use only manufacturer-approved lubricants.

A well-maintained screw and barrel can dramatically improve mixing efficiency and prevent mechanical stress on other parts of your granulator.

2. Gearbox and Lubrication System: The Power Center

The gearbox transmits power from the motor to the screw, so its health directly affects performance and noise levels.

- Change oil regularly: Follow the manufacturer's recommended oil type and replacement interval. Dirty oil can cause gear wear or bearing failure.

- Listen for abnormal sounds: Whining, grinding, or knocking noises are early signs of lubrication or gear damage.

- Keep seals tight: Oil leaks may seem small but can lead to overheating and significant internal wear.

Many modern systems, such as those used in Audop plastic granulator setups, feature efficient lubrication and temperature monitoring to make maintenance easier. Still, routine manual checks remain essential.

3. Heating and Cooling System: Balancing the Temperature

Consistent heating and cooling are crucial for achieving stable granule quality and preventing material degradation.

- Inspect heaters regularly: Replace any damaged heating bands or thermocouples to avoid uneven melting.

- Monitor cooling water flow: Clogged pipes or scale buildup in the cooling system can reduce efficiency and cause overheating.

- Check temperature controllers: Malfunctioning sensors or unstable controllers may lead to poor granulation or even machine shutdowns.

Maintaining the right temperature balance extends the lifespan of both mechanical and electrical components.

Bonus Tips for Longer Life

- Keep your workspace clean: Dust and plastic debris can interfere with sensors and moving parts.

- Tighten bolts periodically: Vibration during operation can loosen mechanical connections.

- Train operators properly: Human error is one of the most common causes of premature equipment wear.

Conclusion

A plastic granulator is an investment - one that pays off best when treated with consistent care. By focusing on the screw and barrel, gearbox and lubrication system, and heating and cooling system, you can ensure years of reliable operation and excellent output quality.

With modern, efficient designs like those from Audop, maintenance is easier than ever - but the human touch still matters. A few minutes of attention today can save you hours of downtime tomorrow.

Top 3 reasons to choose a PVC High Speed Mixer

Upgrade your production line with a PVC High Speed Mixer that delivers faster cycles,uniform batches,and major energy savings.Built for long-term performance and perfect for mixing PVC and other plastics.

PET Bottle Hot Washing Recycling Machine Technology Flow Guide

Discover how a PET Bottle Hot Washing Recycling Machine transforms dirty PET bottles into high-purity recycled flakes.Learn the full technology flow,including sorting,crushing,hot washing,separation,and drying for efficient and high-quality PET recycling.

Ultimate Guide for Selecting a PVC Profile Extrusion Production Line

Discover how to choose the right PVC profile extrusion production line with this clear guide covering core components,key technologies,and selection tips to ensure high-quality,efficient,and stable PVC profile manufacturing.

China Professional Two-Stage Twin Screw & Single Screw Compounding Extruder Manufacturer-Audop

Audop is a leading China manufacturer of two-stage twin screw and single screw compounding extruders,offering high-efficiency,stable,and customized solutions for plastic modification,masterbatch,PVC,WPC,biodegradable and recycled materials.

Exploring the Different Types of Twin Screw Extruders

Discover the key differences between various types of Twin Screw Extruders,including Co-rotating Parallel,Counter-rotating Parallel,and Conical Twin Screw Extruders.Learn how each design works and which is best for your plastic processing needs.