Top 3 reasons to choose a PVC High Speed Mixer

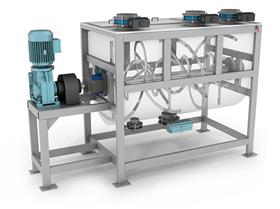

You want a process that is fast, saves money, and works well. A PVC High Speed Mixer gives you all these things. It uses new technology and is easy to use. You can get better mixing and the same good quality every time. These mixers work with many plastics, even recycled PVC. This helps you keep up with new industry changes. They are strong, so they break less and make more products for your business.

Key Feature

- A PVC High Speed Mixer mixes things the same way each time. This helps every batch look and work the same. It makes the product better.

- This mixer works fast and helps make more products quickly. It lets companies fill more orders. It also helps use less material and waste less.

- The PVC High Speed Mixer is built to use less energy. This saves money and helps the environment. It costs less to run.

- The mixer is strong and lasts a long time. It does not break easily. You do not need to fix it often. It is good for busy factories.

- Picking the right mixer size and features helps you mix better. Talk to suppliers to find the best one for your needs.

Mixing Efficiency with PVC High Speed Mixer

Homogeneous Mixing Results

You want every batch to look the same and work well. A PVC High Speed Mixer helps you reach this goal. The mixer has a special shape that makes a strong swirl. The blades spin fast and move materials up and out. This spreads the PVC, PP, PE, or ABS all over the bowl. You get better bulk density and color spread. The mix looks even and works well in your products. You can count on the mixer to give you the same good mix each time.

Faster Production Cycles

Speed is important in factories. When you use a PVC High Speed Mixer, you finish batches faster. The mixer works quickly, so you make more in less time. You also waste less material because mixing is exact. Here are some ways people check for faster work:

- Even spread of stabilizers and colors

- Shorter time for each batch,only requiring 5 to 10 minutes.

- Less waste and more good products

You can fill more orders and meet tight schedules. The mixer helps your business keep moving.

Consistent Quality Output

Quality matters for every product you make. The PVC High Speed Mixer uses smart heat control to keep the temperature right. This system makes sure each batch mixes evenly. You get the right amount of raw materials and good spread of additives. Good mixing makes better plastic products. You can trust the mixer to keep the same quality every time. Your customers will see the difference in your products.

Tip: Using a PVC High Speed Mixer lets you work with many kinds of plastics, even recycled ones. This helps you keep up with changes in the market.

Energy Savings and Cost Benefits

Efficient Design Features

You want machines that use less energy and work well. The PVC High Speed Mixer has a smart design. It uses motors that save power. The blades move materials fast. This means you mix more with less electricity. You help the planet and save money too. Many factories pick these mixers because they are clean and use less energy.

- The mixer uses less power.

- You get more products with less energy.

- The design helps make things in a green way.

Note: Mixers that save energy are liked by people who care about the earth. Using them shows you want to help the environment.

Lower Operating Costs

Saving money is important for every company. The PVC High Speed Mixer helps you spend less in many ways. You pay less for electricity because it uses less power. You also waste fewer materials since mixing is better. When you use less energy and fewer supplies, your costs go down. You can use the extra money to grow or buy new machines.

- Lower bills for energy

- Less waste of materials

- Fewer fixes and less time stopped

Many companies save a lot after they switch to mixers that use less energy. You can use the money you save to make your factory better or give lower prices to buyers.

Comparison to Traditional Mixers

You might wonder how the PVC High Speed Mixer is different from old mixers. Old mixers often use more energy and take longer to finish. They may not follow new rules for clean work. The high-speed mixer has better motors and closed systems to save energy. You also follow strict rules for air and pollution. Many groups and governments give rewards for using mixers that save energy. You can get help to upgrade and avoid fines for breaking rules.

- New mixers help you follow green rules.

- You can get rewards and lower risks.

- Smart mixers help your costs and the planet.

Tip: Picking mixers that save energy helps you follow new rules in North America and Europe. You keep your business safe and help the earth.

Durability and Reliable Performance

Robust Construction

You want a mixer that can handle hard work every day. The PVC High Speed Mixer is made with strong parts and smart design. Its body does not get damaged by chemicals or heat. This means you can use it for many hours without problems. Here are the materials used:

Material | Temperature Resistance | Chemical Resistance |

|---|---|---|

PVC | Up to 140°F (60°C) | Good |

CPVC | Up to 200°F (93°C) | Excellent |

Inside, there are mixing pieces that do not move. These can be helical, spiral, or blade shapes. You pick the type and number you need. The strong motor helps the mixer work fast and smooth. The body does not rust, so you fix it less often.

Tip: The mixer is easy to use. You can change settings and clean it quickly.

Minimal Maintenance

You save time and money because the mixer needs little care. Most PVC High Speed Mixers only need a check once a year. You do not have to stop your work often. The parts are easy to reach, so you can clean and check them fast. This helps you avoid long stops and keeps your factory running.

- Strong build means you fix it less.

- The body does not rust, so it breaks less.

- It is easy to clean, so you finish checks quickly.

Long-Term Industrial Use

You want machines that last for many years. The PVC High Speed Mixer works well for a long time. Mixing tools for soft PVC can last 1 to 2 years before you need new ones. For hard PVC, you may need new tools every 2 to 6 months, but the main mixer keeps working. With good care, these mixers can last 15 to 20 years in busy factories.

Operational Challenge | Solution |

|---|---|

High capacity operation | Strong machine body for long production runs |

Temperature control | Many zones and rotor cooling for best temperatures |

You get the same good results and worry less about problems. Many companies use these mixers for many years in big factories.

You get faster mixing, spend less money, and the mixer works well when you use a PVC High Speed Mixer. When you pick a mixer, remember these tips from experts: Make sure the mixer size fits your batch. Pick one that is built strong and is simple to clean. Choose a motor that saves energy but still has enough power. Talking to suppliers can help you find the best mixer for your needs:

Criteria | Recommendations |

|---|---|

Material Characteristics | Choose mixers for powders or granules for better results. |

Mixing Requirements | Pick based on even mixing or making lots at once. |

Process Conditions | Think about heat and if it can handle chemicals. |

Look at different choices and ask suppliers for help to get the best mixer.

FAQ

How do you clean a PVC High Speed Mixer?

You clean the mixer by opening the lid and removing leftover materials. Use a soft brush or cloth. Wipe the bowl and blades. Check for stuck particles. Clean after each batch for best results.

What materials can you mix in this machine?

You can mix PVC, PP, PE, ABS, and recycled plastics. The mixer works with powders and granules. You get even results with many types of plastic.

How often should you check the mixer for maintenance?

You should check the mixer once a year. Look at the blades, motor, and seals. Clean and inspect parts to keep the mixer working well.

Can you adjust the mixing speed?

Yes, you can adjust the mixing speed. Use the control panel to set the speed for each batch. This helps you get the right mix for different materials.

What safety features does the mixer have?

The mixer has safety locks, emergency stop buttons, and heat sensors. These features protect you and help prevent accidents during operation.

Professional PVC Soft Curtain Production Line Solution: Achieving Efficient Industrial Curtain Production

Explore how a professional PVC soft curtain production line enhances industrial production efficiency,improves product quality,and ensures consistent PVC strip curtain manufacturing.

What Are the Preparatory Steps and Working Procedures for a Mixer

Efficient mixing starts with proper preparation,precise operation,and careful maintenance.Learn key steps to ensure consistent,high-quality blending.

What Are the Components of PVC Pipe Extrusion Line

Discover the key components of a PVC pipe extrusion line and how each part works together to produce high-quality PVC pipes.Learn about the mixer,twin screw extruder,die head,vacuum tank,and more.Explore reliable solutions from Audop PVC Pipe Extrusion.

Several Key Points to Consider When Choosing a Liquid Loss-In-Weight Feeding Machine

Discover essential factors for selecting the right liquid Loss-In-Weight feeding machine.Learn how to ensure precision,stability,and long-term reliability with solutions like the Audop Liquid Loss-In-Weight Feeding Machine.