In plastic compounding, small ingredients decide big results.

In plastic compounding, the spotlight often falls on resin selection, throughput targets, or extruder horsepower. But anyone who has worked closely with a compounding line understands that micro ingredients often play a far bigger role than their percentage suggests. Pigments, stabilizers, lubricants, and flame retardants typically make up less than 5% of a formulation, yet they define color consistency, mechanical performance, and overall process stability. At this scale, precision is not a bonus feature; it is a requirement. A well-designed precision metering automatic batching machine directly addresses one of the core challenges in modern compounding: formulation repeatability.

When grams matter more than tons

From a macro perspective, plastic compounding can appear forgiving. A few kilograms variation in base resin rarely triggers alarms. Micro additives operate under very different rules. A 0.1% deviation in pigment dosing can lead to visible color shifts between batches. Slight underdosing of stabilizers may shorten product lifespan, while excessive lubricants can quietly compromise strength or downstream processing behavior.

These issues often surface long after production-through customer complaints, failed audits, or inconsistent test data. At that point, identifying the root cause becomes difficult, especially in plants still relying on manual micro ingredient weighing. This is one of the most common reasons manufacturers begin asking why micro ingredients matter in plastic compounding at a deeper level.

The hidden cost of manual weighing

Manual dosing may seem acceptable at low volumes, but it scales poorly. Each step introduces variability: operator judgment, environmental vibration, material adhesion, even simple transfer losses. Over time, these small deviations accumulate into batch variation in plastic compounding that no downstream process can fully correct.

Once micro ingredients are off-ratio, the formulation itself is compromised. Neither high-end extruders nor advanced mixing sections can restore accuracy that was lost during weighing. This reality is what drives many processors to compare manual vs automatic micro ingredient weighing systems when quality targets tighten.

Repeatability is the real objective

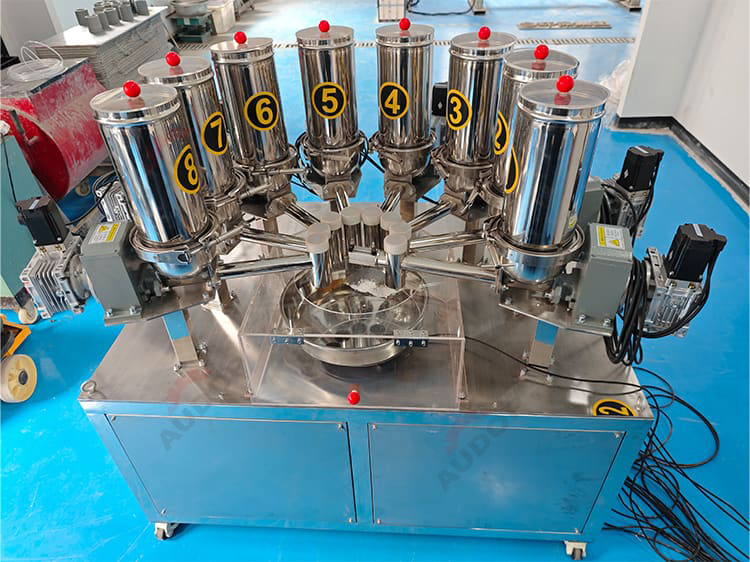

The real value of an automatic micro ingredient batching system for plastics is not convenience-it is repeatable plastic compounding process control. Automated systems execute recipes exactly as defined, regardless of operator, shift, or production speed. Weights are controlled within tight tolerances, and deviations are detected immediately rather than discovered downstream.

This level of consistency answers a key operational question: how to improve formulation consistency in plastic compounding without relying on individual experience or manual discipline. Repeatability becomes a system attribute, not a human one.

What consistency unlocks downstream

Once precision metering for pigments, stabilizers, and additives is achieved, the benefits extend beyond accuracy alone. Quality control becomes data-driven, supported by batch records and material traceability. This is increasingly critical for automotive, electrical, and flame-retardant compounds where compliance and documentation matter as much as performance.

Process stability also improves. Consistent additive dosing leads to predictable melt behavior, reduced torque fluctuation, and fewer unexplained adjustments. Over time, this stability lowers maintenance costs and improves overall equipment effectiveness.

For R&D teams, automated batching removes noise from formulation trials. Small adjustments finally produce meaningful, repeatable results-accelerating development and shortening validation cycles.

Automation as formulation protection

Rather than viewing automation purely as efficiency, many engineers now see it as formulation protection. Modern precision dosing solutions for plastic additives combine load cells, PLC control, and recipe management to ensure every micro ingredient is added correctly, every time. Interlocks and alarms prevent incorrect additions, while closed-loop logic further reduces risk.

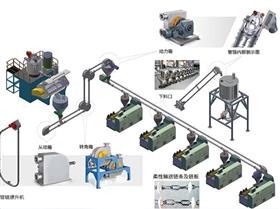

This is why solutions such as Audop's Precision Metering Automatic Batching Machine are increasingly specified by process and quality engineers, not just production managers. A structured automatic batching solution for micro ingredients demonstrates how plastic compounding accuracy is engineered into the process rather than left to chance.

Small inputs, big results

Plastic compounding is full of contradictions. The smallest components exert the greatest influence. The simplest steps create the most complex consequences. And the least visible errors often carry the highest cost.

Understanding this shifts the key question from ''Can we weigh it?'' to ''Can we repeat it-perfectly-every time?'' In an industry demanding tighter tolerances, global consistency, and documented quality, automatic micro ingredient batching is no longer optional.

Because in plastic compounding, success is rarely decided by how many tons you process-but by how precisely you control a few critical grams.

FAQ

What is the difference between manual and automatic micro ingredient weighing?

The key difference between manual vs automatic micro ingredient weighing is repeatability. Manual processes rely on human consistency, which naturally varies. Automatic systems rely on controlled logic, load cells, and recipe management, delivering the same result every time and enabling reliable quality control.

Which applications benefit most from precision micro ingredient dosing?

Applications with strict quality or compliance requirements benefit the most, including automotive compounds, flame-retardant materials, electrical plastics, and color-sensitive products. In these cases, precision metering for pigments, stabilizers, and additives is essential for meeting both performance and documentation standards.

How does automatic batching improve quality control?

Automatic batching systems record every dosing event, creating full batch traceability. This data allows manufacturers to link material performance to exact formulations, making audits, troubleshooting, and continuous improvement far more effective.

Advantages of The Split-Type Vacuum Feeder

Discover the key advantages of the Split-Type Vacuum Feeder-an energy-efficient,low-noise,and easy-to-maintain material conveying system.Ideal for plastics,food,and pharmaceutical industries,the Audop split-type vacuum feeder ensures clean,flexible.

Plastic Shredders and Their Impact on Industrial Recycling

Plastic shredders play a key role in industrial recycling,reducing waste,improving efficiency,and supporting sustainability across multiple sectors.

How to Operate the Pipe Chain Conveyor More Effectively and the Methods for Handling Faults

Learn practical ways to operate the pipe chain conveyor more efficiently,reduce downtime, and handle common faults with ease.Discover expert tips and reliable equipment like the Audop Pipe Chain Conveyor for better material handling performance.

Ultimate Guide for Selecting a PVC Profile Extrusion Production Line

Discover how to choose the right PVC profile extrusion production line with this clear guide covering core components,key technologies,and selection tips to ensure high-quality,efficient,and stable PVC profile manufacturing.

Horizontal Plow Mixer Troubleshooting: Causes and Solutions for Abnormal Discharge in Industrial Mixing

Looking for a reliable Horizontal Plow Mixer for efficient powder and granule blending?Discover how Audop's advanced plow mixer design ensures smooth discharge,uniform mixing,and easy maintenance.