Plastic Crusher: Recycling and Manufacturing Solution

The Audop Plastic Crusher is a powerful and efficient solution for recycling plastic waste directly from your production line. Designed with high-speed blades, durable construction, and easy maintenance, it helps manufacturers turn scrap materials into reusable granules for continuous production. Whether you're dealing with injection molding waste, extrusion leftovers, or defective parts, this crusher ensures consistent size reduction and stable performance. By integrating the Audop Plastic Crusher into your manufacturing process, you can reduce raw material costs, minimize waste, and take a big step toward sustainable, eco-friendly production.

In today's world of fast-paced production and growing plastic consumption, the question of what to do with leftover materials and scrap has become a big one. From injection molding factories to extrusion workshops, tons of plastic waste are generated every day. But instead of throwing it all away, manufacturers now turn to an essential machine that gives plastic a second life-the plastic crusher.

Turning Waste into Value

A plastic crusher is exactly what it sounds like-a machine that crushes plastic. But in practice, it's far more than that. It's a recycling and production tool that helps companies reduce waste, lower costs, and improve efficiency. The machine works by cutting or grinding plastic scraps-like sprues, rejected products, or defective parts-into smaller, uniform granules. These granules can then be easily reused in the manufacturing process, either by mixing them with virgin material or by feeding them directly back into production.

For manufacturers looking for reliable performance and long-term value, the Audop Plastic Crusher is a great choice. It's designed for efficiency, with high-speed rotating blades and durable construction that can handle various types of plastics-from soft film to hard engineering plastics.

Inside the Machine

A good plastic crusher is built with several key components that work together smoothly:

- Feeding Hopper: Where the waste plastic enters the machine. A well-designed hopper ensures safe and consistent feeding.

- Cutting Chamber and Blades: The heart of the crusher. Sharp and wear-resistant blades rotate at high speed to break down the plastic.

- Screen Mesh: Determines the size of the output granules. A finer mesh produces smaller pieces suitable for direct reuse.

- Motor and Transmission System: Provides the crushing power. A strong motor ensures the crusher runs efficiently, even under heavy load.

- Discharge System: Collects the crushed material, often equipped with a blower or conveyor for easy handling.

Why It Matters in Recycling and Manufacturing

Using a plastic crusher isn't just about managing waste-it's about optimizing resources. By recycling on-site, factories can save a significant amount of raw material and reduce disposal costs. It also minimizes environmental impact by lowering the demand for new plastic production.

In injection molding workshops, for instance, water sprues and defective parts can be crushed and reused immediately. This closed-loop recycling process ensures consistent material quality while cutting costs. The Audop Plastic Crusher helps achieve this by providing stable performance and easy maintenance, making it a valuable partner in sustainable production.

The Future of Smart Recycling

As industries move toward greener production, machines like the plastic crusher are becoming even more advanced. Intelligent control systems, noise reduction designs, and energy-efficient motors are setting new standards for the future of recycling. With such improvements, plastic crushing isn't just a necessity-it's becoming a smart investment.

Final Thoughts

The plastic crusher represents more than just a piece of equipment; it's a bridge between recycling and manufacturing. It turns waste into opportunity, drives sustainability, and helps manufacturers stay competitive in an environmentally conscious world. Whether you're running a small molding shop or a large-scale production line, integrating a reliable crusher can make all the difference.

Main Factors Affecting Mixing Time in High Speed Mixing Machines

Improve your production efficiency with the Audop High Speed Mixing Machine.Learn the key factors that affect industrial mixing time-material properties,blade design,batch size,temperature control,and operator settings-to achieve faster,more consistent mixing results.

Exploring the Different Types of Twin Screw Extruders

Discover the key differences between various types of Twin Screw Extruders,including Co-rotating Parallel,Counter-rotating Parallel,and Conical Twin Screw Extruders.Learn how each design works and which is best for your plastic processing needs.

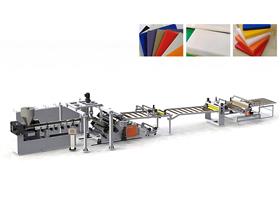

PP PE ABS PVDF PVC Thick Plate Extrusion Line: Ultimate Guide

Discover how PP,PE,ABS,PVDF,and PVC thick plate extrusion lines work,key features,applications,and how to choose the right production system for your factory.

Emerging Trends Shaping Plastic Extruders in 2026

Plastic Extruders in 2026 feature smart manufacturing,AI,and sustainable materials,boosting efficiency,quality,and market growth.

Components and Core Equipment of Powder Centralized Feeding System

Discover the key components and working principles of a powder centralized feeding system.Learn how the Audop Powder Centralized Feeding System enhances efficiency,reduces dust,and ensures safe,automated material handling for modern manufacturing.