PP PE ABS PVDF PVC Thick Plate Extrusion Line: Ultimate Guide

In the world of modern plastics processing, thick plate extrusion stands as one of the most versatile and value-driven manufacturing methods. From chemical-resistant PVDF plates to impact-tough ABS boards and structural-grade PP/PE sheets, industries rely on these materials for durability, stability, and long-term performance. Behind this production capability lies the engineered precision of the PP PE ABS PVDF PVC Thick Plate Extrusion Line-a system designed to deliver consistent thickness, high surface quality, and exceptional mechanical properties.

Whether you're exploring new equipment, optimizing your current process, or simply curious about how these robust plates are produced, this guide walks you through everything you need to know about technology, workflow, applications, and key selection criteria. For full technical details and equipment specifications, you can also refer to the Audop PP PE ABS PVDF PVC Thick Plate Extrusion Line.

1. What Is a Thick Plate Extrusion Line?

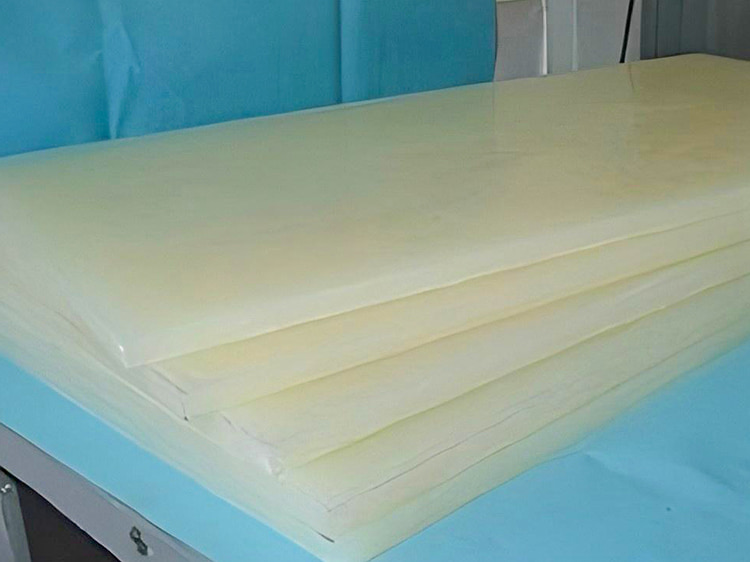

A thick plate extrusion line is a specialized production system designed for manufacturing thermoplastic plates with thicknesses typically ranging from 3 mm to 60 mm or more. Unlike thin sheet extrusion, thick plate extrusion requires stronger melt strength, higher pressure stability, advanced cooling, and precise thickness control across the entire plate width.

Core materials include:

- PP (Polypropylene): Lightweight, chemical-resistant, widely used in environmental and industrial applications.

- PE (Polyethylene): Excellent toughness and impact resistance.

- ABS (Acrylonitrile Butadiene Styrene): Strong, rigid, and easy to machine.

- PVDF (Polyvinylidene Fluoride): High-end engineering plastic; outstanding chemical resistance and thermal stability.

- PVC (Polyvinyl Chloride): Cost-effective, fire-retardant, ideal for industrial boards.

Each material behaves differently during extrusion, and a professional production line is engineered to handle them with precise control.

2. How the Thick Plate Extrusion Line Works

A thick plate extrusion line integrates multiple systems that work in harmony to convert raw resin into finished, high-quality plates. The basic workflow includes:

Step 1: Resin Feeding & Plasticizing

Resin pellets (sometimes mixed with additives or recycled materials) are fed into the extruder.

- High-torque screw design ensures powerful plastification.

- Controlled temperature zones gradually melt the material without degradation.

Step 2: Extrusion Through a T-Die

The melted material flows through a precisely machined T-die.

- Die lip adjustments allow thickness control.

- Melt filtration improves clarity, mechanical strength, and consistency.

Step 3: Calendering & Thickness Calibration

A multi-roller calendering system presses the melt into a thick plate.

- Roller temperature balance ensures smooth surfaces.

- High pressure prevents air bubbles and internal stress.

- Servo-controlled roller gaps determine final thickness to within ±0.1–0.3 mm.

Step 4: Cooling, Trimming & Haul-Off

The plate is gradually cooled to maintain structure and flatness.

- Air and water cooling systems reduce residual stress.

- Edge trimming ensures clean dimensions.

- Powerful haul-off units prevent plate deformation during transport.

Step 5: Cutting & Stack-Off

The final product is cut to size using:

- Saw cutting

- Guillotine cutting

- CNC trimming (optional)

Stack-off units maintain plate stability to avoid warping.

3. Key Features of a High-Quality Thick Plate Extrusion Line

To consistently produce industrial-grade plates, the extrusion line must deliver:

High Output & Energy Efficiency

Modern screw designs increase throughput while reducing energy demand.

Uniform Thickness & Smooth Surface

Advanced T-die flow channels and precision calendering systems ensure flawless plates.

Material Flexibility

A professional line-such as the Audop PP PE ABS PVDF PVC Thick Plate Extrusion Line-is engineered to process a wide range of thermoplastics with equal stability.

Intelligent Control

Fully automated PLC systems:

- Maintain temperature precision

- Monitor pressure

- Record production data

- Control line speed for consistency

Long-Term Stability & Easy Maintenance

Heavy-duty frames, corrosion-resistant materials, and modular components help keep downtime low and productivity high.

4. Applications of PP PE ABS PVDF PVC Thick Plate Extrusion Line

- Packaging: PP and PE boards are widely used in the production of packaging materials, such as containers, boxes, and trays. Their durability and resistance to chemicals make them ideal for protective packaging.

- Signage and Advertising: These boards are often used for making outdoor signage, billboards, and displays due to their ability to withstand harsh weather conditions.

- Construction: PP and PE boards are used in the construction industry for applications like temporary flooring, wall coverings, and insulation.

- Automotive: In the automotive sector, these boards are used for interior components, such as dashboards, door panels, and trim parts.

- Furniture and Décor: The versatility of PP and PE boards also extends to the furniture industry, where they are used to produce components like tabletops, shelving, and decorative elements.

5.How to Choose the Right PP PE ABS PVDF PVC Thick Plate Extrusion Line

Selecting the right PP PE ABS PVDF PVC Thick Plate Extrusion Line for your needs depends on several factors, such as production volume, required board specifications, and budget. Here are some tips for making the best choice:

- Production Capacity: Consider the desired output per hour and ensure that the extrusion line you choose can meet your production demands.

- Customization Options: Some extrusion lines offer greater flexibility in terms of adjustable board thickness, size, and finish. If you need customized boards, ensure that the machine can accommodate these requirements.

- Energy Efficiency: Look for an extrusion line that is energy-efficient to reduce operational costs.

- Automation: Many modern extrusion lines come with automated control systems, which can enhance the precision and efficiency of production.

6. Final Thoughts

A well-designed PP PE ABS PVDF PVC thick plate extrusion line is more than a piece of equipment-it's a complete production ecosystem that blends engineering, materials science, and precise control. Whether you're producing chemical-resistant PVDF plates, structural PP sheets, or versatile ABS boards, the right extrusion line determines your efficiency, product quality, and long-term competitiveness.

For full specifications, configuration options, and system advantages, you can explore the Audop PP PE ABS PVDF PVC Thick Plate Extrusion Lineand discover how professional engineering can elevate your entire production workflow.

What Are the Key Plastic Recycling Machines and How Do They Work

Plastic Recycling Machines like shredders,granulators,and extruders process,clean,and reshape plastics for efficient recycling and quality results.

Dust-free Feeding Station: The Ideal Solution for Efficient Feeding

Discover how the Audop Dust-Free Feeding Station provides a cleaner,safer,and more efficient solution for powder and bulk material feeding.Improve production quality,protect worker health,and maintain a dust-free workspace.

Ultimate Guide for Selecting a PVC Profile Extrusion Production Line

Discover how to choose the right PVC profile extrusion production line with this clear guide covering core components,key technologies,and selection tips to ensure high-quality,efficient,and stable PVC profile manufacturing.

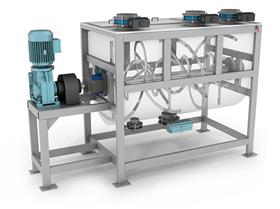

Top Tips for Choosing the Ideal SRL-Z Series Vertical Mixing Unit

Discover the SRL-Z Series Vertical Mixing Unit—high-speed mixing,consistent uniformity,automation,energy efficiency,and optimal space use.Learn features,applications,maintenance tips,and how to choose the right model for your factory.