Dust-free Feeding Station: The Ideal Solution for Efficient Feeding

In today's industrial world, efficiency and cleanliness go hand in hand. Whether handling fine powders, additives, or bulk solids, dust control during the feeding and unloading process has become a top priority for ensuring product quality and protecting worker safety. That's where the Dust-Free Feeding Station comes in - an innovative solution that transforms material handling into a cleaner, safer, and more efficient process.

Why Dust-Free Feeding Matters

If you've ever seen a cloud of powder rise when opening a bag of raw material, you already know how messy traditional feeding systems can be. Floating dust doesn't just make cleaning a headache - it can contaminate products, damage sensitive equipment, and even threaten worker health. Over time, airborne dust builds up, reducing efficiency and increasing maintenance costs.

A dust-free feeding system eliminates these issues by combining airtight feeding ports, powerful dust extraction, and smooth material transfer. The result? A cleaner environment, reduced material waste, and improved feeding accuracy.

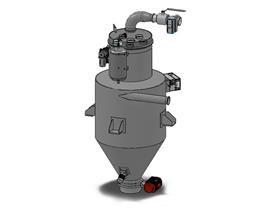

How the Audop Dust-Free Feeding Station Works

The Audop Dust-Free Feeding Station is designed with both efficiency and safety in mind. When an operator places a bag of material on the feeding table and opens it, the system automatically activates its dust extraction unit. Dust particles are captured by a high-efficiency filter before they can escape into the air, and purified air is released back into the workspace.

This simple but effective design not only minimizes dust but also speeds up the feeding process. Operators can focus on accuracy and productivity instead of constant cleanup.

Key Benefits of a Dust-Free Feeding Station

1. Cleaner Work Environment

By preventing dust from escaping, the system keeps the workspace clean and significantly reduces maintenance and cleaning costs.

2. Improved Health and Safety

Operators are protected from inhaling harmful particles, helping companies meet occupational safety standards and creating a more comfortable working environment.

3. Enhanced Efficiency

Smooth material feeding minimizes waste and ensures steady production rates - ideal for high-output manufacturing lines.

4. Consistent Product Quality

With zero dust contamination, product purity and consistency are maintained, which is critical for industries like pharmaceuticals, food, and plastics.

Applications Across Industries

The Audop Dust-Free Feeding Station is suitable for a wide range of industrial applications. It's particularly effective in industries handling fine powders such as calcium carbonate, starch, pigments, and resin - materials known for generating airborne dust.

Its adaptable design allows easy integration with existing feeding or conveying systems, supporting manual, semi-automatic, or fully automated feeding operations.

Why Choose Audop?

Audop specializes in advanced material handling and feeding solutions designed for real-world industrial needs. Their Dust-Free Feeding Station combines intelligent engineering with robust construction, ensuring long-lasting performance and compliance with environmental and safety standards.

When you choose Audop, you're not just choosing a piece of equipment - you're investing in cleaner production, greater efficiency, and a safer workplace.

Conclusion

In an era where efficiency, sustainability, and workplace safety define competitiveness, adopting a dust-free feeding system is no longer optional - it's essential. A dust-free feeding station not only keeps your facility spotless but also enhances product quality, streamlines operations, and safeguards your team.

If your goal is to modernize your feeding process and create a cleaner, more productive working environment, the Audop solution is exactly what you need.

PET Bottle Hot Washing Recycling Machine Technology Flow Guide

Discover how a PET Bottle Hot Washing Recycling Machine transforms dirty PET bottles into high-purity recycled flakes.Learn the full technology flow,including sorting,crushing,hot washing,separation,and drying for efficient and high-quality PET recycling.

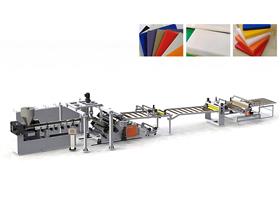

PP PE ABS PVDF PVC Thick Plate Extrusion Line: Ultimate Guide

Discover how PP,PE,ABS,PVDF,and PVC thick plate extrusion lines work,key features,applications,and how to choose the right production system for your factory.

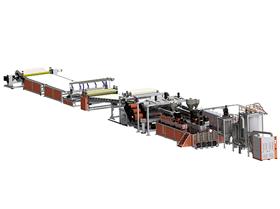

From Process to Control: How to Significantly Enhance the Extrusion Efficiency of PC Sheets

Learn how to improve PC sheet extrusion efficiency through optimized process control,stable plasticization,advanced automation,and high-performance production lines.

Something you need to know about plastic crushers

Discover how plastic crushers work, their advantages,applications,and how they help reduce waste and improve recycling efficiency.Learn key features and benefits for manufacturers and recyclers.

Everything You Need to Know About Pneumatic Conveying Equipment

Pneumatic Conveying Equipment:key components,system types,and expert tips for efficient,safe bulk material handling in industrial applications.