Ribbon Mixer

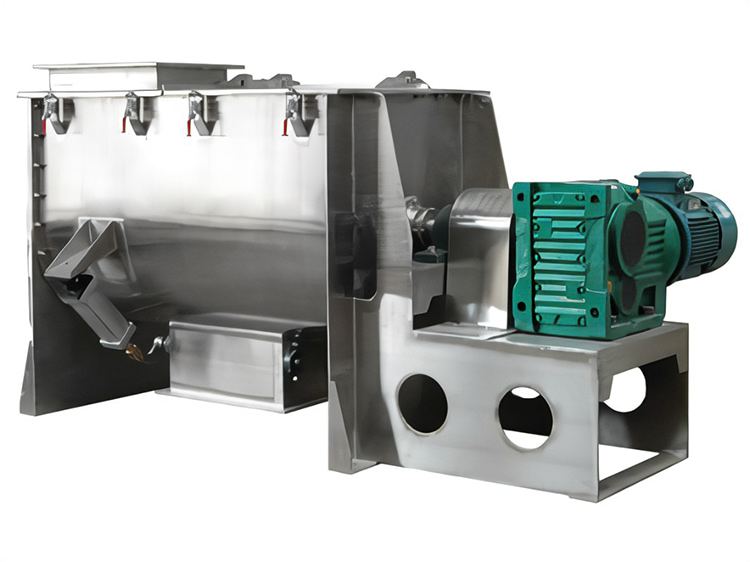

- This machine has a horizontal cylinder, and the inner and outer two-layer spiral ribbons have a unique structure. It features stable operation, reliable quality, low noise, long service life, convenient installation and maintenance. There are various mixer structures available, making it a multi-functional mixing equipment with a wide range of uses. The mixing effect of the horizontal ribbon mixer is not affected by the particle size and density, ensuring consistent mixing quality for different materials.

- It has fast mixing speed and high mixing uniformity. Scrapers can be installed on the spiral ribbons, which also achieve a good mixing effect for viscous materials, further expanding its application scope.

- According to the mixing requirements of different materials (special materials need to be cleaned after each mixing), different spiral ribbon structures can be adopted. Heating and drying jackets are also available for customers to choose, meeting the personalized production needs of different enterprises.

- The forward and reverse rotating spiral ribbons are installed on the same horizontal shaft, forming a low-power mixing environment. The stable mixing process reduces the damage to fragile materials. A flying knife structure can be added to play a crushing role, and a liquid spraying system can also be added to fully and uniformly mix liquids and powders, enhancing the functionality of the horizontal ribbon mixer.

- A cleaning door can also be opened on the horizontal machine body for users to clean. The overall height of the equipment is relatively low, facilitating installation and saving factory space.

- It has a large loading coefficient and a small equipment floor area, helping enterprises save production space and improve space utilization efficiency.

Overview

What is a Ribbon Mixer?

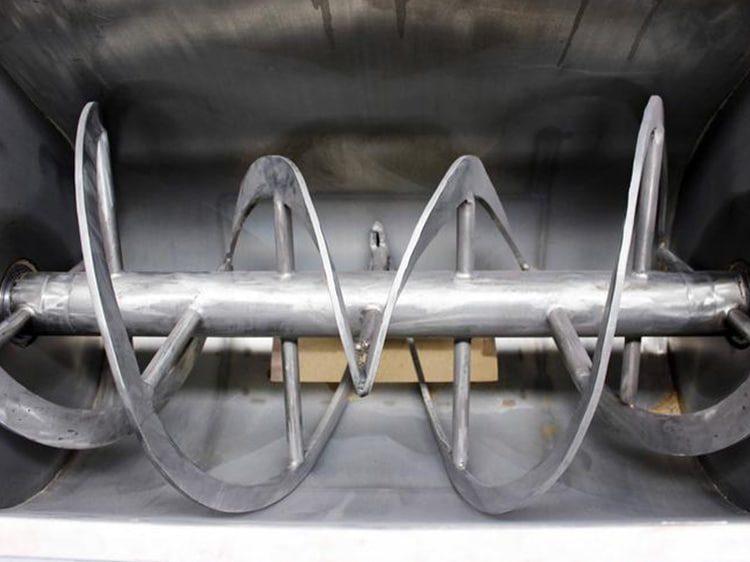

The horizontal ribbon mixer is composed of a U-shaped container, ribbon mixing blades and transmission components. The ribbon-shaped blades are generally made into double-layer or three-layer structures. The outer-layer spiral gathers materials from both sides to the center, while the inner-layer spiral conveys materials from the center to both sides, forming convective mixing. This horizontal ribbon mixer design ensures efficient material circulation for optimal mixing results.The ribbon mixer has an excellent mixing effect for viscous or cohesive powder particles, as well as for mixing liquids and pasty materials into powder particles. The cylinder cover can be made into a fully open door, which facilitates equipment cleaning and product changeover, making it a practical choice for various production needs.The horizontal ribbon mixer is mainly used for mixing powder with powder and powder with liquid, and it is especially capable of mixing paste-like, viscous or high-specific-gravity materials. It is a versatile mixing equipment widely applied in different industrial mixing scenarios.Due to the difficulty in cleaning viscous materials, it is more suitable for occasions with large output and infrequent product variety changes, helping manufacturers improve production efficiency and reduce downtime.

The horizontal ribbon mixer features a horizontal cylinder, with inner and outer two-layer spiral ribbons installed on the main shaft. It has a unique structure, ensuring stable operation, reliable quality, low noise, long service life and convenient installation and maintenance. There are various spiral ribbon structures available, enabling fast mixing speed and high mixing uniformity. Especially for viscous materials, scrapers can be installed on the spiral ribbons to better adapt to the mixing of thick and pasty materials, enhancing its applicability to special material mixing requirements.he structure of the horizontal ribbon mixer mainly consists of a reducer, a coupling, a main shaft bearing, a machine base, a ribbon assembly, a discharge valve, a cylinder, a cleaning port, a feed port, a liquid spraying device, an observation port, a main shaft and a main machine motor. All components work together to ensure the stable and efficient operation of the mixer.For the horizontal ribbon mixer, the movement of the spiral ribbons on the mixing shaft enables the inner and outer spiral ribbons to turn over materials in a wide range. The inner spiral ribbons move materials to both sides, while the outer spiral ribbons move materials from both sides to the inside, making materials mix back and forth. Another part of the materials is pulled by the spiral ribbons to move along the axial and radial directions, thus forming a convective cycle for thorough mixing.Thanks to the mixing effect of the above-mentioned movements, materials can be quickly and uniformly mixed in a short time, which greatly improves the production efficiency of enterprises.The horizontal ribbon mixer has a good mixing effect for viscous or cohesive powder particles, as well as for mixing liquids and pasty materials into powder particles. The cylinder cover can be made into a fully open door, which is convenient for equipment cleaning and product changeover, meeting the hygiene and production flexibility needs of factories.

Working Principle of Ribbon Mixer:

The horizontal ribbon mixer uses the inner and outer diameter spirals installed on the mixing shaft to drive the materials in the barrel, allowing the mixer to turn over the materials in a large range inside the barrel, laying a foundation for uniform mixing.In terms of the mixer structure, the spirals are designed as inner-outer and left-right opposite spirals. When the mixer works, the inner spiral drives the materials near the axis to rotate around the axis and pushes them from the inside to both sides in the axial direction; the outer spiral drives the materials near the barrel wall to rotate around the axis and pushes them from both sides to the inside in the axial direction. This causes the materials to undergo convective circulation and shear mixing in the barrel, completing the fast and uniform mixing of materials in a short time. This scientific design ensures the high performance of the horizontal ribbon mixer.

Application Range of Ribbon Mixer:

The horizontal ribbon mixer is applied in the mixing of solid-solid (i.e., powder and powder) and solid-slurry (i.e., powder and glue slurry) in industries such as pesticides, veterinary drugs, food, chemicals, biology, aquaculture, ceramics, refractory materials, plastics and compound fertilizers. It is also especially suitable for mixing viscous materials, making it an essential mixing equipment for various industrial fields.

Core Advantages of Industrial Ribbon Mixers:

- High-Efficiency Mixing Capacity: The dual-ribbon design of the industrial ribbon mixer creates a fast mixing environment, which can significantly shorten the mixing time. The conveying capacity of some models of high-efficiency ribbon mixers can reach 8 times that of standard conical screw mixers, greatly improving mixing efficiency.

- Wide Application Range: This versatile industrial ribbon mixer is suitable for mixing various materials, including powder-powder, powder-slurry, and viscous material mixing. It can handle materials ranging from fine powders to coarse particles, and can even be applied in processes such as coating powder blending or liquid addition.

- Strong Operational Flexibility: The industrial ribbon mixer offers multiple capacity options, with working capacities ranging from 3 cubic feet to 515 cubic feet, meeting diverse production requirements. Meanwhile, it can be equipped with a frequency converter to achieve smooth startup and speed adjustment, reducing wear during full-load startup.

- Convenient Cleaning & Maintenance: Modern industrial ribbon mixers adopt a hygienic design, and their U-shaped cylinder structure ensures dead-angle-free mixing, facilitating easy cleaning and discharge. Some models are also equipped with fully open cylinder lids or detachable agitators, allowing thorough cleaning and preventing cross-contamination between batches.

Selection Guide for Industrial Ribbon Mixers:

Select Based on Material Characteristics: For free-flowing powders, standard models of industrial ribbon mixers can meet the needs. For easy-adhesive materials, choose ribbon mixers with high-gloss or mirror-polished inner surfaces to reduce material residue. When handling wear-resistant materials, models equipped with Hardox liners can be considered to enhance wear resistance.

Determine Based on Production Capacity: When selecting an industrial ribbon mixer, batch size is a key consideration. The working capacity of the mixer is usually 30%-70%; insufficient capacity cannot guarantee mixing effect, while excessive capacity will reduce mixing efficiency. It is recommended to select a suitable model according to the per-batch processing volume, ensuring the equipment operates within the optimal capacity range.

Operational Precautions for Industrial Ribbon Mixers:

To ensure the optimal performance and long service life of the industrial ribbon mixer, the following points should be noted during operation:

- Load Control: Do not exceed 70% of the equipment’s maximum capacity to ensure sufficient mixing space and effect.

- Startup Sequence: Start the mixer before feeding materials, or use a frequency converter to achieve smooth startup and reduce equipment stress.

- Regular Inspection: Regularly check the gap between the ribbon and the container wall to ensure it is within the design tolerance range.

- Cleaning & Maintenance: Thoroughly clean the equipment after each use to prevent material accumulation and cross-contamination.

Technical Parameters

Technical Parameters

| Model | Effective Volume(l) | Motor Power(kw) | Speed(r/min) |

DLH-100 | 35-60 | 2.2 | 58 |

DLH-150 | 60-80 | 3 | 53 |

DLH-300 | 100-150 | 4 | 53 |

DLH-500 | 180-300 | 7.5 | 49 |

DLH-1000 | 350-600 | 11 | 42 |

DLH-1500 | 550-800 | 15 | 42 |

DLH-2000 | 700-1000 | 18.5 | 42 |

DLH-3000 | 1000-1500 | 18.5 | 37 |

DLH-4000 | 1500-2000 | 22 | 37 |

DLH-5000 | 2000-3000 | 30 | 31 |

DLH-6000 | 2200-3500 | 37 | 31 |

DLH-8000 | 3000-4200 | 45 | 27 |

DLH-10000 | 3200-5000 | 55 | 27 |

DLH-12000 | 3600-6000 | 55 | 23 |

DLH-15000 | 5000-8000 | 75 | 23 |

DLH-20000 | 8000-10000 | 90 | 19 |

DLH-30000 | 10000-15000 | 110 | 17 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Reaction Kettle

- Strong sealing & precise temperature control: Supports heating and cooling, and can stably maintain the temperature range required for reactions.

- Efficient stirring: Equipped with professional stirring devices to ensure uniform material mixing and sufficient reaction.

- Suitable material selection: Common stainless steel material, acid and alkali corrosion resistance, suitable for different reaction systems.

- Safe and reliable: Equipped with multiple pressure and temperature monitoring devices and explosion-proof devices to reduce reaction risks.

- Flexible specifications: Volumes range from milliliter level to cubic meter level, which can meet the needs from laboratory small-scale tests to industrial mass production

PVC High Speed Mixer

- All important parts (bowl, mixing tool, electrical control) are manufactured in AUDOP Company, which ensure the quality of machine.

- All material in contact with product is SS304 or aluminum alloy and the product will not be contaminated.

- Short mixing time, easy and convenient to clean high output.

- Mixing tool coated with wear-resistant material, which can increase service life and past dynamic and balance test,running smoothly.

- Mature product technology based on mixing blade with high tip speed (up to 40m/sec).

- High throughput rate at low, specific energy consumption.

- Rapid, perfect after-sales service.

High speed Hot and Cooling Mixer Machine

Highlighted Features:

1. Material: All contact parts are made of S.S.304 stainless steel.

2. Treatment: Inner wall is highly polished, with layers for heat preservation.

3. Shaft Seal: metal labyrinthy seal + air-purge seal +oil seal, triple seal to guarantee no leak of material.

4. Temperature control: With control system to monitor material temperature in real time.

Two thermal resitstors, one is for controlling temperature, the other one is for overheat alarm.

5. Driving Motor: With Frenquency convetor to realise speed adjustment of main shaft.

6. Cover-opening: With pneumatic system as well as hand wheel to guarantee the cover can be opened even no air and electricity.Horizontal Mixer

- High Mixing Efficiency: The specially designed mixing device and rotation method of the horizontal mixer make materials form multiple vortices in the barrel, greatly accelerating the mixing speed.

- High Mixing Uniformity: Even if there are differences in specific gravity and particle size of materials, the staggered mixing blades of the horizontal mixer tumble and sprinkle quickly and violently, which can still achieve excellent mixing effect.

- Wide Application Range: The horizontal mixer is suitable for mixing a variety of materials, such as powders, semi-fluids, etc.

- Easy Operation: The horizontal mixer has a compact structure, simple operation, and easy daily maintenance and upkeep.