PET Bottle Flakes Washing Recycling Line

Features

Main featured functions of Bottle flakes washing machine

1.Bottles bales are opened by de-baling for continuous operation unpacking with high unpacking capability.

2. Metal separation analyses small and bulk materials with material height over 100 mm.

3.Equipped with label separator for removing the labels.

4.The dirty, caps sand, rock will removed in pre-washer machine.

5.Blade material of crusher adopts SKD11 through special manufacture process and heat treatment.

6. Adopt boiling hot water which sterilizes and further gets rid of contaminants such as glues.

7.Separating PP/PE films and PET flakes by floating machine.

8.After centrifuge dryer, the final production moisture content less than 1%.

1.Bottles bales are opened by de-baling for continuous operation unpacking with high unpacking capability.

2. Metal separation analyses small and bulk materials with material height over 100 mm.

3.Equipped with label separator for removing the labels.

4.The dirty, caps sand, rock will removed in pre-washer machine.

5.Blade material of crusher adopts SKD11 through special manufacture process and heat treatment.

6. Adopt boiling hot water which sterilizes and further gets rid of contaminants such as glues.

7.Separating PP/PE films and PET flakes by floating machine.

8.After centrifuge dryer, the final production moisture content less than 1%.

Overview

What is PET Bottle Flakes Washing Recycling Machine?

What is PET Bottle washing Recycling Machine used for?

1. PET Bottle Washing Recycling Machine takes dirty PET bottles as its input and outputs clean PET flakes.

2. Suitable for contaminated bottles, post-consumer bottles, waste bottles from production line.

3. The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent

film and sheets, etc. The top class flakes can be used to blow bottles again.

PET Bottle Flakes Washing Recycling Line Market

Recycling of PET bottle is one of the most lucrative businesses as the demand for the Re-cycled PET material is growing rapidly.

PET washing line has been conceived specially for processing of contaminated PET consumer bottles.

The PET flakes has such high purity after washing and separation that it can be directly processed by extrusion or PSF machines into new products

Brief Introduction of Plastic Bottle flakes recycling line

1.We AUDOP has developed a complete Washing line which is designed with experience, care and latest technology for a trouble free operation for all kind of Plastics.

2.PET Bottle Washing Recycling Machine takes dirty PET bottles as its input and outputs clean PET flakes. This is an export commodity which can be sold and used for many creative applications. And the flakes can be further processed and reutilized with high commercial value.

3.The production capacity we can make on the PET Bottle washing and recycling line ranging from 500kg to 3000kg per hour.

4.The main purpose is intent to get clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line.

5.All the wasted water is recycled and reused by Water Treatment System in the washing line.

The dirty water from a washing process is collected, cleaned and thenre-circulated. That significantly reduces the amount of fresh water that would have been needed.

We promise to :

1. Offering most competitive price, most complete solution, turn-key project.

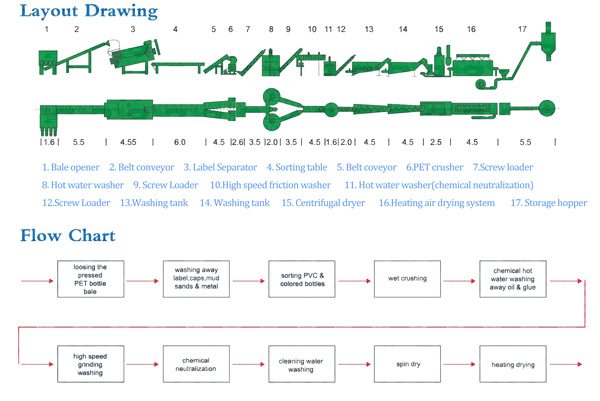

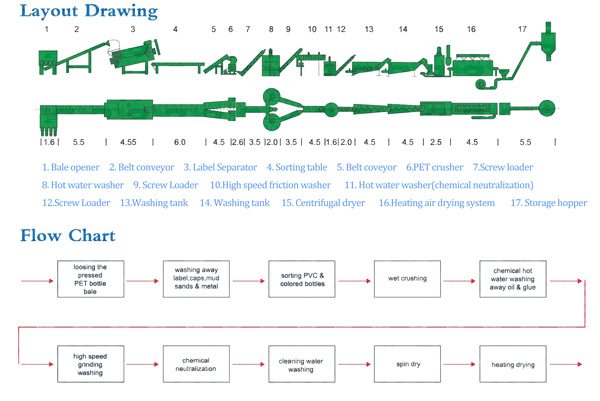

2. We can make machine layout diagram according to client's workshop floor plan.

3. The whole line can be designed on the basis of how dirty the flakes are, we can accord to custom's requirements to choose suitable machines.

4.Final products has good quality. Final products humidity below 1%, impurities100ppm, PVC content 100ppm.

5.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service life.

6.World famous brand components applied on the production line.

Please kindly be noted that the above pictures and parameters of our machines are for reference only. The color of the machines is changeable, and the main structure can be specially designed according to customers' requirements. Please feel free to make an inquiry and ask for more needed details.

What is PET Bottle washing Recycling Machine used for?

1. PET Bottle Washing Recycling Machine takes dirty PET bottles as its input and outputs clean PET flakes.

2. Suitable for contaminated bottles, post-consumer bottles, waste bottles from production line.

3. The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent

film and sheets, etc. The top class flakes can be used to blow bottles again.

PET Bottle Flakes Washing Recycling Line Market

Recycling of PET bottle is one of the most lucrative businesses as the demand for the Re-cycled PET material is growing rapidly.

PET washing line has been conceived specially for processing of contaminated PET consumer bottles.

The PET flakes has such high purity after washing and separation that it can be directly processed by extrusion or PSF machines into new products

Brief Introduction of Plastic Bottle flakes recycling line

1.We AUDOP has developed a complete Washing line which is designed with experience, care and latest technology for a trouble free operation for all kind of Plastics.

2.PET Bottle Washing Recycling Machine takes dirty PET bottles as its input and outputs clean PET flakes. This is an export commodity which can be sold and used for many creative applications. And the flakes can be further processed and reutilized with high commercial value.

3.The production capacity we can make on the PET Bottle washing and recycling line ranging from 500kg to 3000kg per hour.

4.The main purpose is intent to get clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line.

5.All the wasted water is recycled and reused by Water Treatment System in the washing line.

The dirty water from a washing process is collected, cleaned and thenre-circulated. That significantly reduces the amount of fresh water that would have been needed.

We promise to :

1. Offering most competitive price, most complete solution, turn-key project.

2. We can make machine layout diagram according to client's workshop floor plan.

3. The whole line can be designed on the basis of how dirty the flakes are, we can accord to custom's requirements to choose suitable machines.

4.Final products has good quality. Final products humidity below 1%, impurities100ppm, PVC content 100ppm.

5.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service life.

6.World famous brand components applied on the production line.

Please kindly be noted that the above pictures and parameters of our machines are for reference only. The color of the machines is changeable, and the main structure can be specially designed according to customers' requirements. Please feel free to make an inquiry and ask for more needed details.

Technical Parameters

Customers viewing this product may be also interested in: