Bigger blades don’t always mean better crushing

In the world of plastic recycling, there's a persistent belief that refuses to die: the bigger the blade, the better the crushing. On paper, it sounds logical. Larger blades look stronger, more aggressive, and somehow more ''industrial'' .But anyone who has actually worked with a plastic crushing machine on a production floor knows the truth is far more nuanced.

In fact, oversized blades can quietly sabotage efficiency, energy consumption, and even final material quality.

Let's break down why blade size alone doesn't guarantee better crushing-and what really matters when choosing the right plastic crusher.

Why ''bigger'' often backfires in plastic crushing

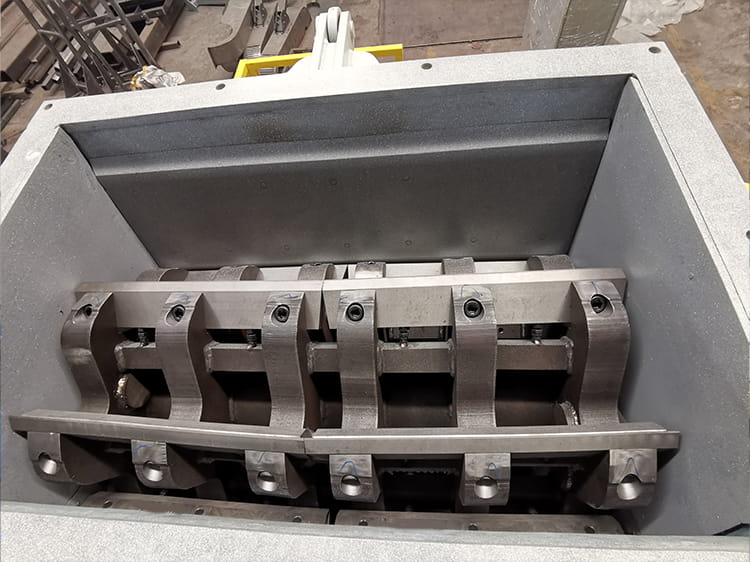

A modern plastic crusher or plastic granulator isn't just a cutting tool-it's a balance of geometry, speed, torque, and material flow. When blades become excessively large, several problems start to appear.

First, oversized blades increase rotational inertia. That means higher startup loads, more stress on the motor, and unnecessary energy loss. In real production, this often shows up as higher electricity bills without any meaningful gain in throughput.

Second, bigger blades don't always improve cutting efficiency. For materials like PET bottles, HDPE containers, or thin-walled packaging, aggressive blade profiles can tear instead of shear. The result? Uneven flakes, excessive fines, and dust-exactly what downstream extrusion and pelletizing lines don't want.

This is why many plastic bottle crusher designs today favor optimized blade angles and tighter clearances over brute size.

Crushing is about control, not brute force

If you look closely at high-performing plastic shredders and plastic waste recycling machines, you'll notice something interesting: blade size is rarely the star of the show.

What actually matters more is:

Blade geometry – Shearing angles designed for specific polymers

Rotor speed – Too fast creates heat; too slow reduces output

Cutting chamber design – Determines material circulation and residence time

Screen configuration – Controls final particle size consistency

In other words, efficient crushing is about controlled cutting, not overpowering the material.

This is especially critical when processing mixed plastics, films, or brittle regrind where excessive force leads to melting, clogging, or unstable operation.

Where Audop takes a smarter approach

At Audop, the design philosophy behind every plastic crushing machine starts with a simple question: What problem is the customer actually trying to solve?

Instead of defaulting to oversized blades, Audop focuses on application-specific engineering:

Optimized blade dimensions matched to material type

High-strength alloy steel with extended wear life

Stable rotor balance for low vibration and quiet operation

Modular designs that simplify maintenance and blade replacement

Whether the machine is used as a plastic granulator for injection molding scrap or as a primary crusher in a recycling line, the goal is consistent output-not exaggerated cutting power.

That's why Audop machines often run cooler, quieter, and longer, even when processing demanding materials.

Bigger blades vs. better results: a real-world example

Consider a recycling line handling post-consumer plastic packaging. Switching to larger blades might increase the initial 'bite,' but operators often report:

Higher power draw

More frequent jams

Increased blade wear

Inconsistent particle size

By contrast, a well-matched plastic crusher with moderate blade size and optimized geometry delivers smoother feeding, cleaner cuts, and better downstream performance.

In short: bigger blades may look impressive, but better engineering keeps the line running.

Plastic crushing machine: Frequently Asked Questions

Q1: Does a larger blade increase crushing capacity?

Not necessarily. Capacity depends on rotor speed, motor power, cutting chamber volume, and material type-not blade size alone.

Q2: Are big blades better for hard plastics?

Hard plastics require proper blade hardness and cutting angle, not oversized dimensions. Incorrect blade design can cause cracking instead of clean cuts.

Q3: How do I choose the right plastic crushing machine?

Start with your material (PET, HDPE, film, rigid scrap), desired output size, and daily throughput. A professional supplier will recommend blade design accordingly.

Q4: Is maintenance harder with larger blades?

Yes. Larger blades are heavier, harder to handle, and often increase downtime during replacement or sharpening.

Q5: Can one machine handle multiple plastic types?

Yes-if the design allows blade and screen flexibility. This is where a well-engineered plastic crushing machine really shows its value.

Final thoughts

In plastic recycling, performance isn't measured by blade size-it's measured by stability, efficiency, and output consistency.

Bigger blades might look powerful, but smarter blade design delivers better crushing. And in a competitive recycling market, smart always beats big.

If you're planning to upgrade or expand your crushing system, look beyond appearances. Focus on engineering, experience, and real-world results-the things that truly matter once the machine starts running.

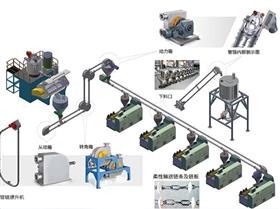

How to Operate the Pipe Chain Conveyor More Effectively and the Methods for Handling Faults

Learn practical ways to operate the pipe chain conveyor more efficiently,reduce downtime, and handle common faults with ease.Discover expert tips and reliable equipment like the Audop Pipe Chain Conveyor for better material handling performance.

How to Choose a Volumetric Feeder

Learn how to choose the right volumetric feeder for your production line.Discover the differences between single and double screw volumetric feeders and find out which one suits your materials best.

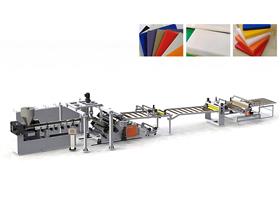

PP PE ABS PVDF PVC Thick Plate Extrusion Line: Ultimate Guide

Discover how PP,PE,ABS,PVDF,and PVC thick plate extrusion lines work,key features,applications,and how to choose the right production system for your factory.

2026 Powder Particle Metering Equipment Purchase Guide

A complete 2026 guide to choosing powder and particle metering equipment,including multi-component suction weighing systems,incremental weighing scales,additive dosing machines,and precision automatic batching solutions.Learn how to select the right model

Important Guidelines for Operating and Maintaining Vertical Mixer Dryer

Learn essential tips for safely operating and maintaining your vertical mixer dryer.Improve drying efficiency and extend machine life with the Audop Vertical Mixer Dryer.