The Extruder of HDPE Pipe Production Line

The extruder is the heart of any HDPE pipe production line - it determines the pipe's strength, smoothness, and overall quality. Designed with precision and efficiency in mind, the Audop HDPE Pipe Extrusion Line offers excellent melt uniformity, stable operation, and intelligent control for consistent, high-performance HDPE pipe manufacturing. Whether you're producing water supply pipes, gas pipes, or cable protection conduits, Audop's advanced extrusion system ensures reliable output and long-term durability.

When you look at a sturdy HDPE (High-Density Polyethylene) pipe carrying water or gas underground, it's easy to overlook the technology behind its creation. But at the heart of every HDPE pipe production line lies a powerful and precise machine - the extruder. This single piece of equipment is the true workhorse that determines the quality, consistency, and efficiency of the entire production process.

What Exactly Does the Extruder Do?

In simple terms, the extruder is where plastic magic happens. HDPE pellets are fed into the hopper, gradually heated and melted as they travel through a long, temperature-controlled barrel. Inside, a rotating screw pushes and mixes the molten polymer, building pressure until it's forced through a die that shapes it into a perfect pipe.

The process may sound straightforward, but the secret lies in fine-tuning temperature zones, screw design, and extrusion speed. A well-designed extruder ensures the melt is uniform, stable, and perfectly suited for pipe forming - which translates to smoother surfaces, higher strength, and longer-lasting pipes.

Components That Make It All Work

A modern extruder is much more than a simple screw and barrel. It's a blend of mechanical precision and intelligent control. Key components include:

- Feeding System: Regulates the flow of HDPE pellets into the barrel for consistent output.

- Screw and Barrel: The screw's geometry - length, compression ratio, and pitch - directly affects the melting efficiency and mixing quality.

- Heating and Cooling Zones: Precise temperature control ensures that HDPE melts evenly without degradation.

- Die Head and Calibration Unit: After extrusion, the hot melt passes through a die to form the pipe shape and then through a calibration system that cools and sets the dimensions accurately.

Auxiliary components of HDPE pipe production line:

1. Die (forming device): The main molding component for forming the product.

2. Calibration device: Fixed shape and dimensions, ensuring product smoothness.

3. Cooling device: Provides adequate cooling to prevent deformation.

4. Pulling device: Uniformly draws out the product and adjusts its dimensions by adjusting the speed.

5. Cutting device: Cuts the continuously extruded product into desired lengths.

6. Stacking or winding device: Used to neatly stack cut-to-length hard products or to wind soft products into rolls. In the practical application of PE pipes in water supply pipes, different sizing structures can be selected based on the material, production speed, and quality requirements. Currently, two main types of PE pipe sizing devices are popular: cylindrical sizing sleeves and sheet-type modular sizing sleeves.

Every part plays a crucial role in achieving the flawless, round, and durable pipes used across water supply, gas transportation, and cable protection industries.

Why Extruder Quality Matters

Inconsistent extrusion can lead to uneven pipe walls, weak spots, or even complete product failure. That's why investing in a reliable system like the Audop HDPE Pipe Extrusion Line can make all the difference. These lines are designed for stability, efficiency, and superior melt homogeneity, ensuring each pipe meets the highest performance standards.

Moreover, advanced extruders today are integrated with smart control systems that automatically adjust processing parameters. This not only improves output quality but also reduces material waste and energy consumption - a win for both productivity and sustainability.

The Beating Heart of Pipe Production

You could say that the extruder is the 'engine” of the HDPE pipe manufacturing process - everything else depends on it. From the strength of the final pipe to its smoothness and uniformity, it all starts with the perfect melt inside the extruder barrel.

For manufacturers seeking reliability and precision, the Audop HDPE Pipe Extrusion Line offers a complete solution built around a high-performance extruder that turns raw HDPE into excellence.

2026 Powder Particle Metering Equipment Purchase Guide

A complete 2026 guide to choosing powder and particle metering equipment,including multi-component suction weighing systems,incremental weighing scales,additive dosing machines,and precision automatic batching solutions.Learn how to select the right model

Why Are High-Speed Mixers So Widely Used

Discover why high-speed mixers are essential in modern manufacturing.Learn how the Audop High Speed Mixing Machine delivers fast,consistent,and efficient performance across plastics,chemicals,and food industries.

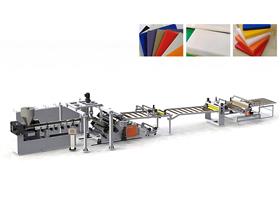

PP PE ABS PVDF PVC Thick Plate Extrusion Line: Ultimate Guide

Discover how PP,PE,ABS,PVDF,and PVC thick plate extrusion lines work,key features,applications,and how to choose the right production system for your factory.

Maintenance and Operation of Parallel Twin Screw Extruder

Learn how to properly maintain and operate a Parallel Twin Screw Extruder to ensure efficient plastic compounding and long-term performance.Discover expert tips on daily operation,maintenance routines,and best practices from Audop.

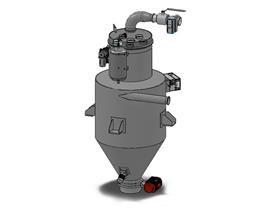

Everything You Need to Know About Pneumatic Conveying Equipment

Pneumatic Conveying Equipment:key components,system types,and expert tips for efficient,safe bulk material handling in industrial applications.