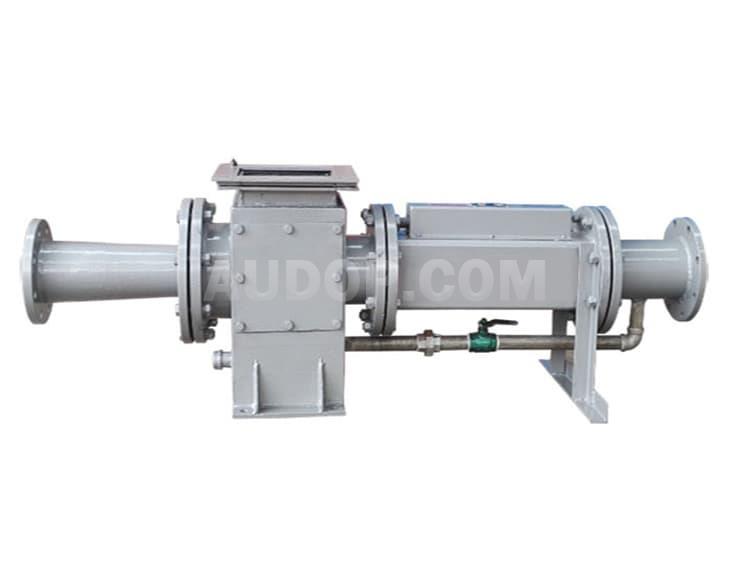

Pneumatic Conveying Material Seal Pump

- Simple structure and reliable operation: The pneumatic conveying equipment - material seal pump allows materials to enter the pump at normal pressure. With the uniquely designed injection device, materials are sent into the conveying pipe, and the pneumatic pressure difference is used to convey materials along the pipe to the material receiving destination. The overall structure is simple and the operation is extremely reliable.

- Low wear and long service life: Due to the adoption of continuous conveying, low pressure and large air volume, the flow velocity in the pipe is low and constant, so the wear is small, and the service life of the entire system equipment is long.

- Convenient and flexible layout: The material seal pump can be arranged in forms such as single pump with single pipe, multiple pumps with common pipe, multiple pumps with common air source, etc. according to the specific conditions of the system. The pipes can be arranged horizontally, vertically or obliquely upward to meet the ever - changing layout requirements of the project.

- Fully sealed and pollution - free conveying, meeting the environmental protection requirements of itself and the quality requirements of the conveyed materials in the project: Since the material seal pump adopts low positive pressure and fully sealed conveying, external substances cannot enter the pipe, so it will not cause any change in the properties of the required materials.

- Stable conveying: Due to the adoption of continuous conveying with low pressure and large air volume, there is no pipe blocking phenomenon.

- Simple operation: Since the material seal pump has only limited moving parts and the supporting component is only the Roots blower, the main body control only requires "start" and "stop" operations, no manual on - duty is needed, only patrol is required. Due to the simple process system of the continuous conveying pump, the logical relationship of the configured control system is also simple, and the operation and maintenance are simple and reliable.

- Low requirement on the quality of air source: Due to the adoption of continuous conveying form and the fact that the conveying power air source generally uses Roots blower, the power air source generally does not need to set up a purification system, and only has certain requirements on air volume and pressure. Independent air source or air compressor station air source (centralized air source) commonly used in engineering can be used.

- High system reliability: The low - pressure pneumatic continuous conveying system composed of pneumatic conveying material seal pump equipment has reliability that cannot be achieved by conveying systems composed of any other pneumatic conveying equipment. This is because: the low - pressure continuous conveying system generally uses Roots blower (high - pressure centrifugal fan or air compressor can also be used according to the situation), and the high reliability of Roots blower determines the reliability of the system. The equipment itself is simple, without frequent actions of valves in the conventional pneumatic conveying process, so the equipment failure rate is greatly reduced. The pneumatic conveying system composed of low - pressure pneumatic conveying equipment - material seal pump generally has a small number and types of equipment, making the entire system simple and reliable. The continuous conveying pressure is stable without any impact load.

- Economical and reasonable, low cost and low system operation cost: The low - pressure continuous pneumatic conveying system composed of pneumatic conveying material seal pump equipment has the characteristics of low cost and excellent operation indicators due to the above - mentioned characteristics.

Overview

The pneumatic conveying material seal pump is a new type of powder pneumatic conveying equipment, belonging to the low-pressure dilute-phase conveying category. It uses the ejection effect of high-speed air flow to convey powdery materials, and achieves the best use effect within the equivalent distance of 450m and lifting height of 40m.At present, it is widely used in the medium and short-distance conveying of dry and loose powders such as fly ash, alumina powder, dry kiln ash, cement powder and other dry loose powdery materials.

Working Principle of Pneumatic Conveying Material Seal Pump:

The material seal pump uses the air jet effect to make air drive ash particles to convey ash to the ash silo. The material seal pump is mainly composed of four parts: nozzle, cylindrical pump body, nozzle adjustment device and bottom vaporization device. The energy of the material seal pump during operation comes from two parts: one part is the kinetic energy of the fan, and the other part is the potential energy of the material column.The higher the material column, the greater the potential energy and pressure, and the corresponding larger the conveying capacity; on the contrary, the smaller it is.When the material seal pump works normally, it maintains a certain material level height. When the discharge volume of the electric precipitator increases in a short time while the material seal pump still works normally, the material level height will rise naturally. With the increase of the material level height, the material pressure increases, the potential energy increases, and the conveying capacity increases accordingly until the system reaches automatic balance. When the discharge volume of the electric precipitator decreases in a short time while the material seal pump still works normally, the material level height will decrease naturally. With the decrease of the material level height, the material amount decreases, the potential energy decreases, and the conveying capacity decreases accordingly until the system reaches automatic balance.

Operating Conditions of Pneumatic Seal Pump:

- A necessary condition for the normal operation of the material seal pump is that there must be a certain material seal height. The pressure of the silo material level must be greater than the positive pressure inside the material seal pump during operation. The positive and negative pressures are isolated by the material level pressure, and the wind pressure of the fan conveys the material away. Therefore, a certain material level height is essential.

- A dust collector must be installed on the material receiving silo, and the air exhaust volume of the dust collector must be greater than the air intake volume of the ash conveying fan. Otherwise, when the air intake volume is greater than the air exhaust volume, the pressure inside the material receiving silo will be forced to increase, resulting in unbalanced system pressure, high pipeline resistance, and the incoming air will flow back from the material seal pump to the part above the silo, making the material seal pump unable to work normally.

Maintenance of Material Seal Pump:

- Before the operation of the material seal pump, an appropriate amount of engine oil should be added to the movable air duct box to lubricate the oil seals at both ends of the movable air duct. An appropriate amount of mechanical oil should be added to the reducer of the adjustment mechanism according to the position of the oil standard line. Use N46 oil in winter and N68 oil in summer. Change the oil within one month after the initial commissioning, and generally change it twice a year afterwards.

- Frequently check the filter cloth in the vaporization device, usually once every six months.

- No other maintenance is required, and there are few wearing parts. Check the scouring condition of the tapered and divergent pipes in the diffuser pipe after one year, and replace them if they are severely worn.

Technical Parameters

Technical Parameters

| Model | Delivery Value(t/h) | Required Airflow(m³/min) | Required Wind Pressure(kpa) | Power(kw) |

| LFB100 | 0-5 | 9-14 | 30-100 | 5.5-37 |

| LFB125 | 3-10 | 12-20 | 11-42 | |

| LFB150 | 10-16 | 20-28 | 7.5-75 | |

| LFB200 | 18-35 | 32-40 | 18-132 | |

| LFB250 | 30-55 | 55-70 | 22-285 | |

| LFB300 | 50-90 | 80-100 | 30-280 | |

| LFB400 | 90-150 | 92-150 | 45-350 |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.

Positive Pressure Conveying System

- The positive pressure conveying system is convenient for installing branch pipelines, which can convey materials to multiple places at the same time, with high production efficiency.

- The air leakage position of the positive pressure conveying system is easy to find, and the dust removal requirement for air is not high.

- The system has small conveying resistance and less wear on the pipeline.

- The positive pressure conveying system has a long conveying distance, which can reach more than 1000m.

- Air supplement pipes can be installed inside and outside the conveying pipeline, and air supplement and blockage removal can be carried out in a variety of ways.

Pneumatic Conveying Pump

- High Energy Efficiency: Due to the reasonable fluidization structure, the material fluidization state is good, and the air consumption is significantly lower than that of similar products. After years of production and research, our company has improved the fluidization structure for many times, which greatly improves production efficiency and reduces energy consumption, helping users save operating costs.

- High Material-Gas Ratio: With good fluidization effect and low air consumption, the material-gas ratio is naturally high. Through laboratory tests, when the equivalent distance is within 500 meters, the material-gas ratio can reach more than 30Kg (ash)/Kg (gas), ensuring efficient material conveying.

- Low Material Flow Rate: The material flow rate during conveying is low, which results in small wear of the equipment's valves and pipelines and long service life of vulnerable parts, reducing the frequency of equipment maintenance and replacement.

- Strong Adjustment Function: It has various adjustment methods such as primary and secondary air intake adjustment, which can make the system operate under the optimal air consumption ratio and excellent fluidization state, adapting to different material conveying conditions.

- Unique Blockage Removal Method: It adopts a back-suction blockage removal method, which is simple, easy to implement and reasonable in operation. It only needs to lead the material-gas mixture to the silo or flue inlet through the blockage removal valve and pipeline, ensuring smooth operation of the conveying system.

- Easy Solution for Supporting Facilities: Due to low air consumption and low speed, the silo material-gas separation and filtration equipment can be smaller than that equipped with general bin-type pumps, and the air pollution caused is also small, meeting environmental protection requirements.

- Small Energy Consumption Coefficient: The energy consumption coefficient of the bin-type pump conveying system is below 65KW.h/t.m, which is more energy-saving compared with similar conveying systems.

- High Degree of Automation: It adopts a programmable (PLC) control system, and the entire working process can be fully automated. The system can be set to automatic or manual operation mode. The main control cabinet is installed in the system control room, reducing manual operation intensity and improving operation accuracy.

High-Power Vacuum Loader

- High-Power Vacuum Loader is a model specially developed for scenarios with large material consumption, catering to the high-volume material needs of industrial production.

- The motor power, feeding pipe diameter and hopper capacity all adopt enlarged configurations to meet the material handling requirements of large-scale industrial operations.

- Equipped with microcomputer control, it provides material shortage and overload alarms, ensuring safe and reliable operation of the material conveying system.

- It has a small size, occupies little space and features flexible operation, making it easy to integrate into different industrial production line layouts.

- Customizable one-machine multi-hopper type vacuum loaders are available to meet the diverse material conveying needs of different industrial production lines.

Electric Vacuum Feeder

- The power source of the whole set of equipment is compressed air, and no power supply is used;

- The equipment is easy and simple to disassemble and clean;

- The equipment operates with very low noise and does not generate heat or oil pollution;

- The powder conveying process is carried out in a closed environment, without dust leakage.

Vacuum Feeder

- Simple and automatic control, with arbitrary setting of suction time, easy and convenient operation.

- Hygienic closed conveying, no dust leakage, no cross-contamination, in line with GMP standards, and sterile equipment can be provided.

- It occupies a small space, can complete the conveying of powders in narrow spaces, makes the working space neat and elegant, and is not limited by the length of the distance.

- Clean and dust-free operation, no dead ends, and quick and convenient disassembly, assembly, cleaning, and material change.

- Economical: One machine can be used for multiple sets of equipment in turn, with high efficiency and energy saving, no need for warm-up and standby, and low operation and maintenance costs.